Fast join propane hose is revolutionizing how we deal with propane. This complete information dives deep into each side, from set up and security to upkeep and choosing the proper hose on your wants.

This information will equip you with the information to confidently work with fast join propane hoses. We’ll cowl all the pieces from understanding the benefits and downsides to meticulously detailing the security precautions, set up procedures, and varied upkeep ideas. We’ll additionally discover the different sorts, parts, and the way to decide on the proper hose on your particular software.

Overview of Fast Join Propane Hose

Fast join propane hoses have revolutionized the best way propane is dealt with and transported, providing a big enchancment over conventional strategies. Their speedy connection and disconnection capabilities improve security and effectivity, particularly in conditions demanding frequent modifications of location. This text explores the intricacies of those hoses, their advantages, drawbacks, and essential security concerns.Fast join propane hoses, not like their conventional counterparts, are designed for speedy and safe connections, minimizing the danger of leaks and spills.

This attribute makes them perfect for cell purposes and industries the place time is a important issue. They supply a noticeable enhancement in office security by minimizing the potential for human error and unintended spills throughout the connection course of.

Goal and Perform

Fast join propane hoses are particularly designed to move propane fuel safely and effectively between a supply and an equipment. They leverage a safe coupling mechanism to quickly join and disconnect the hose from the propane tank and the equipment. This fast connection system dramatically reduces the danger of leaks and spills in comparison with conventional strategies, notably in cell or high-volume utilization eventualities.

Benefits of Fast Join Hoses

The advantages of fast join propane hoses prolong past velocity and security. They provide a notable benefit by way of time financial savings, minimizing downtime and enhancing productiveness. Fast join techniques permit for fast and straightforward connections, saving beneficial time in varied purposes. That is particularly useful in cell settings or purposes the place frequent connections are required. The security issue can be a key benefit, decreasing the danger of leaks and spills in comparison with conventional strategies.

Browse the a number of parts of cna jobs agency to realize a extra broad understanding.

Diminished danger of harm and environmental harm are vital benefits.

Disadvantages of Fast Join Hoses

Whereas fast join hoses supply quite a few advantages, some drawbacks want consideration. The price of fast join fittings will be greater than conventional fittings, which may have an effect on the general price of the system. The complexity of the short join mechanism also can result in potential points with upkeep and repairs, notably if not dealt with accurately. These mechanisms, whereas designed for velocity, may also be inclined to wreck from mishandling or overuse, which may compromise their integrity.

Supplies Utilized in Building

Fast join propane hoses are usually constructed from high-quality supplies which are proof against the corrosive results of propane and different associated chemical substances. The hose itself is usually constructed from versatile and sturdy supplies, akin to bolstered rubber or artificial polymers. These supplies are chosen for his or her means to resist the strain and stress inherent in propane transport.

Fittings, essential parts for connection, are sometimes constructed from sturdy supplies, akin to metallic alloys or bolstered plastics. The selection of supplies straight influences the sturdiness, reliability, and longevity of the hose.

Discover out additional about the advantages of how much does an f150 weigh that may present vital advantages.

Varieties of Fast Join Fittings

Numerous forms of fast join fittings can be found, every tailor-made for particular purposes. These fittings are designed to securely and quickly join and disconnect the hose from the propane tank and the equipment. Examples embrace bayonet-style fittings, twist-lock fittings, and cam-lock fittings, every differing of their mechanisms and design options. The collection of the suitable becoming is essential to make sure a safe and leak-free connection.

An in depth understanding of the different sorts is crucial for applicable choice and utilization.

Security Precautions

Security ought to all the time be paramount when utilizing fast join propane hoses. Common inspections of the hose and fittings are important to determine any indicators of injury or put on. All the time make sure the becoming is securely locked earlier than use. It’s essential to retailer the hose in a protected and dry location when not in use. Thorough coaching on the right use and upkeep of the hose is crucial to keep away from accidents.

The right use of fast join fittings is essential for security, and common inspection is important to forestall leaks and accidents. The potential hazards related to improper use shouldn’t be underestimated.

Set up and Utilization

Correct set up and utilization of quick-connect propane hoses are essential for security and effectivity. Neglecting these procedures can result in harmful conditions, from leaks to unintended fires. Following a step-by-step strategy ensures a safe and dependable connection.Connecting and disconnecting quick-connect propane hoses includes particular procedures to forestall leaks and guarantee a protected connection. This part particulars the method, from preliminary connection to correct disconnection, and highlights the significance of security measures all through the whole process.

Connecting a Fast-Join Propane Hose

Connecting a quick-connect propane hose includes a number of key steps. First, guarantee each the hose and the equipment are turned off. Subsequent, align the quick-connect becoming on the hose with the corresponding becoming on the equipment. Firmly push the becoming till it clicks into place, indicating a safe connection.

Disconnecting a Fast-Join Propane Hose

Disconnecting a quick-connect propane hose is equally necessary for security. First, flip off the propane provide on the equipment. Subsequent, firmly press the discharge lever on the quick-connect becoming. This can disengage the becoming, permitting you to take away the hose safely.

Instruments for Fast-Join Hose Set up

Correct instruments are important for environment friendly and protected set up. A wrench is required for tightening connections, and security glasses must be worn to guard your eyes from flying particles. A sturdy work floor can be necessary for stability throughout the set up course of. Make sure the instruments are applicable for the dimensions and kind of quick-connect becoming.

Sustaining a Fast-Join Propane Hose System

Common upkeep is important for prolonging the lifetime of your quick-connect propane hose system. Examine the hose for any indicators of injury, akin to cracks, kinks, or put on and tear. Substitute the hose if any harm is detected. Be certain that all connections are tight and safe. Common inspection helps stop leaks and ensures the system operates safely.

Comparability of Fast-Join Strategies

Completely different quick-connect propane hose connection strategies exist, every with its personal benefits and downsides. Some strategies use a lever-based system for connection and disconnection, whereas others make use of a twist-lock mechanism. The selection of technique typically is determined by the particular equipment and hose kind. Think about the particular necessities of the system when choosing the suitable technique. A correct understanding of every technique’s strengths and weaknesses is essential for making an knowledgeable resolution.

Upkeep and Troubleshooting: Fast Join Propane Hose

Correct upkeep of your quick-connect propane hose is essential for security and longevity. Neglecting routine checks can result in leaks, malfunctions, and probably hazardous conditions. This part particulars important upkeep procedures and customary troubleshooting steps. Understanding these points will empower you to proactively preserve your propane system.

Common Upkeep Guidelines

Common upkeep is important for stopping points and guaranteeing the protected operation of your propane system. The next guidelines supplies a structured strategy to sustaining your quick-connect propane hose.

Uncover the essential parts that make 3 point quick hitch the best choice.

- Visible Inspection: Completely examine the hose for any indicators of injury, akin to cracks, kinks, or put on and tear. Look at the quick-connect fittings for correct alignment and safe connections. Take note of the areas the place the hose flexes.

- Stress Check: Periodically strain check the hose to detect any leaks. Comply with producer directions for applicable strain and testing procedures.

- Becoming Inspection: Examine the quick-connect fittings for any indicators of corrosion or harm. Make sure the connection mechanism is functioning accurately.

- Storage: Retailer the hose in a cool, dry, and guarded space, away from direct daylight, excessive temperatures, and harsh chemical substances. Hold the hose off the bottom to forestall harm from particles.

Frequent Issues and Options

Fast-connect propane hoses, like another tools, are inclined to sure points. Understanding these issues and their options can stop accidents and dear repairs.

- Leaky Connections: Leaky connections are a typical downside. Make sure the quick-connect fittings are correctly engaged. If the leak persists, test for harm to the hose or fittings. Substitute the hose or fittings if crucial.

- Kinks and Bends: Keep away from kinking or bending the hose excessively. These bends can harm the hose, resulting in leaks or breakage. Make sure the hose is routed correctly to keep away from sharp bends.

- Corrosion: Corrosion can weaken the hose materials, growing the danger of leaks or breakage. Examine the hose for indicators of corrosion and change it if crucial.

- Injury to the Fast-Join Fittings: Make sure the quick-connect fittings are in good situation. Malfunctioning fittings can stop correct connection or trigger leaks. Substitute broken or worn fittings.

Significance of Inspections and Preventative Upkeep

Common inspections and preventative upkeep are essential for stopping critical points together with your propane system. By proactively addressing potential issues, you may keep away from pricey repairs and make sure the security of your operation. Early detection of minor points typically prevents extra vital, and probably hazardous, issues.

Troubleshooting Desk

This desk Artikels potential causes and treatments for frequent quick-connect hose points.

| Downside | Potential Trigger | Treatment |

|---|---|---|

| Leaky connection | Unfastened or broken quick-connect fittings, kinked hose | Tighten fittings, examine for harm, straighten the hose |

| Hose breakage | Excessive strain, sharp bends, extended publicity to harsh situations | Substitute the hose, enhance routing to keep away from sharp bends, retailer in appropriate situations |

| Corrosion | Publicity to moisture, chemical substances, or harsh environments | Examine for corrosion, change the hose if crucial, retailer in a dry space |

| Malfunctioning quick-connect fittings | Put on and tear, improper dealing with | Substitute worn or broken fittings, deal with fittings with care |

Security Issues

Propane, whereas a handy and environment friendly vitality supply, presents inherent security dangers. Understanding these dangers and implementing correct security protocols is paramount when working with propane, notably when utilizing quick-connect hoses. Neglecting security measures can result in critical accidents or property harm. An intensive understanding of potential hazards and applicable security tools is essential for protected operation.

Significance of Propane Security, Fast join propane hose

Propane fuel is extremely flammable and may trigger extreme burns, asphyxiation, and explosions if not dealt with accurately. Correct security measures are important to forestall accidents and guarantee a safe working setting. Recognizing potential hazards and implementing preventative measures considerably reduces the danger of incidents.

Potential Hazards of Fast Join Propane Hoses

Fast-connect propane hoses, whereas designed for ease of use, current particular hazards. Defective connections, improper set up, or compromised hose integrity can result in leaks, which in flip enhance the danger of fires or explosions. Utilizing broken or outdated hoses additional exacerbates these dangers. Incorrectly related or improperly secured quick-connect fittings are additionally potential sources of leakage.

Important Security Tools

Utilizing the suitable security tools is important for mitigating dangers when dealing with propane. This features a correctly functioning carbon monoxide detector, hearth extinguishers applicable for flammable fuel fires, and protecting eyewear and clothes. Security glasses, gloves, and a flame-resistant jacket must be worn when working close to open flames or probably hazardous areas.

Significance of Correct Air flow

Satisfactory air flow is essential for stopping the buildup of propane fuel, which might create a flammable environment. Guaranteeing adequate airflow within the space the place propane tools is used is paramount. That is notably necessary in confined areas the place fuel can accumulate quickly.

Security Protocols for Dealing with Fast Join Propane Hoses

| Security Protocol | Description |

|---|---|

| Common Inspection | Completely examine the hose, fittings, and connections for any indicators of injury, put on, or leaks earlier than every use. Broken hoses must be instantly changed. |

| Correct Connection | Make sure the quick-connect becoming is securely related to each the equipment and the propane tank. Double-check for correct alignment and tightness to forestall leaks. |

| Air flow | Keep sufficient air flow within the work space to forestall the buildup of propane fuel. Open home windows and doorways or use followers to make sure correct airflow. |

| Flame Safety | Keep away from working close to open flames or sparks. Guarantee all ignition sources are turned off when working with propane. |

| Emergency Procedures | Know and apply emergency procedures, together with learn how to shut off the propane provide and activate emergency response techniques. |

Sorts and Purposes

Fast join propane hoses are important for protected and environment friendly propane supply. Understanding the different sorts obtainable, their capabilities, and applicable purposes is essential for each residential and business customers. This part delves into the assorted forms of fast join propane hoses, their strain scores, and the varied vary of purposes they serve.

Materials and Building Variations

Completely different supplies and building strategies have an effect on a fast join propane hose’s sturdiness, strain resistance, and total efficiency. Choosing the proper kind is crucial for guaranteeing security and longevity.

| Hose Kind | Materials | Stress Score (PSI) | Typical Purposes |

|---|---|---|---|

| Commonplace Metal Braided | Metal braided reinforcement over an artificial inside tube | Usually 200-300 PSI | Residential grills, moveable heaters, and small-scale business purposes |

| Excessive-Stress Strengthened | Strengthened with a number of layers of high-strength materials like fiberglass or Kevlar | 300-500 PSI or greater | Industrial cooking tools, industrial furnaces, and purposes requiring greater strain |

| Versatile Rubber | Versatile rubber inside tube, typically with a braided outer cowl | Usually decrease strain scores (100-200 PSI) | Smaller home equipment, out of doors cooking tools, and conditions the place flexibility is prioritized over excessive strain |

| Specialty Hoses (e.g., Stainless Metal) | Corrosion-resistant chrome steel building | Variable, depending on particular design | Purposes in harsh environments, meals service, and areas the place chemical resistance is important |

Stress Score Issues

The strain score of a fast join propane hose is a important security issue. It dictates the utmost strain the hose can stand up to earlier than failure. Increased strain scores are important for purposes involving high-pressure tools or giant volumes of propane. For instance, a propane tank related to a high-powered business grill requires a hose with a strain score exceeding that of a hose used for a yard barbecue.

Purposes and Industries

Fast join propane hoses are utilized in a wide range of industries and purposes, typically dictated by the strain and setting.

- Residential Use: Fast join propane hoses are frequent in residential settings for grills, patio heaters, and different out of doors home equipment. The flexibleness and ease of connection are extremely valued in these conditions.

- Industrial Kitchens: In business kitchens, fast join hoses are continuously used for connecting propane to stoves, ovens, and different cooking tools. Excessive-pressure scores are sometimes required for the sturdy efficiency of those commercial-grade home equipment.

- Industrial Furnaces: Industrial furnaces and different high-temperature purposes require fast join propane hoses with excessive strain scores and specialised supplies to resist the demanding setting.

- Cellular Propane Tools: Fast join hoses are important for cell propane tools, akin to moveable mills and building instruments. The convenience of connection and disconnection is a big benefit in these purposes.

Environmental Suitability

The suitability of a fast join propane hose for a selected setting is determined by components like temperature extremes, publicity to chemical substances, and the presence of corrosive parts. Choosing the proper hose materials and building is essential to forestall untimely deterioration or failure.

Elements and Options

Understanding the parts and options of a fast join propane hose is essential for protected and environment friendly operation. A well-designed fast join system minimizes the danger of leaks and ensures a safe connection between the propane tank and equipment. This part delves into the specifics of those techniques, highlighting the important function every part performs.

Elements of a Fast Join Propane Hose Meeting

Propane fast join hose assemblies are meticulously designed to facilitate speedy and safe connections. A typical meeting includes a number of important parts.

- Coupling Heads: These are the first parts liable for the short join mechanism. They characteristic a locking mechanism that secures the connection between the propane tank and equipment, stopping unintended disconnections and leaks. Completely different designs exist, from easy lever-operated techniques to extra complicated cam-operated mechanisms. The design straight impacts the convenience and velocity of connection, in addition to the general security of the system.

- Hose Physique: The hose physique is constructed from sturdy supplies, akin to bolstered rubber or plastic, guaranteeing flexibility and longevity. The hose physique usually includes a bolstered outer layer to resist strain fluctuations and exterior impacts.

- Security Reduction Valve: Incorporating a security reduction valve is essential for stopping extreme strain buildup. This valve permits for the managed launch of propane within the occasion of a malfunction or exceeding strain limits. Correctly functioning security reduction valves are important for security throughout operation.

- O-rings and Seals: These important parts guarantee a leak-tight connection between the coupling heads and hose physique. O-rings and seals preserve the integrity of the connection and forestall propane leakage.

Mechanism of Fast Connection

The fast connection mechanism is a key characteristic of those hoses. It leverages particular mechanisms to make sure safe and speedy connections.

- Lever-Operated Methods: These techniques usually make the most of a lever or latch that engages with a corresponding half on the opposite coupling head. This technique is comparatively simple and fast. Lever-operated techniques are sometimes most well-liked for his or her simplicity and ease of use.

- Cam-Operated Methods: These mechanisms typically incorporate a cam-and-slot design. This configuration permits for a safer connection in comparison with lever techniques. Cam-operated techniques usually present a extra sturdy locking mechanism, enhancing security.

- Compression Fittings: Some fast join propane hoses use compression fittings. These fittings depend on compressing the hose physique to create a safe connection. Compression fittings are sometimes used for particular purposes the place a easy, but efficient, connection is required.

Key Options Differentiating Fashions

Completely different fashions of fast join propane hoses fluctuate in options and specs. These variations typically affect the convenience of use, security, and longevity of the hose.

- Supplies of Building: Completely different hose our bodies and coupling heads could also be constructed from varied supplies, every providing distinct properties relating to sturdiness, flexibility, and resistance to environmental components. This impacts the hose’s total lifespan and talent to resist varied situations.

- Stress Rankings: Stress scores specify the utmost strain the hose can stand up to. Increased strain scores are appropriate for extra demanding purposes, akin to industrial settings.

- Working Temperature Vary: The temperature vary inside which the hose capabilities successfully must be thought-about. Working exterior this vary might compromise the hose’s integrity.

- Security Options: Some fashions might incorporate extra security options, akin to computerized shut-off mechanisms, to boost security.

Specs and Options of Fast Join Propane Hose Fashions

A desk outlining the specs and options of varied fast join propane hose fashions is offered beneath. This knowledge permits knowledgeable choices primarily based on particular wants.

| Mannequin | Supplies | Stress Score (PSI) | Temperature Vary (°C) | Security Options | Utility |

|---|---|---|---|---|---|

| QC-100 | Metal, rubber | 150 | -20°C to 60°C | Security Reduction Valve | Residential use |

| QC-200 | Aluminum, bolstered rubber | 200 | -30°C to 80°C | Security Reduction Valve, computerized shut-off | Industrial use, high-pressure purposes |

| QC-300 | Chrome steel, bolstered nylon | 250 | -40°C to 90°C | Security Reduction Valve, computerized shut-off, leak detection | Industrial use, cell purposes |

Selecting the Proper Fast Join Propane Hose

Deciding on the suitable fast join propane hose is essential for protected and environment friendly operation. Improper choice can result in leaks, strain points, and even security hazards. Understanding the important components concerned in choosing the proper hose is paramount for any software.Matching the hose to the particular software is crucial for optimum efficiency and security. A hose designed for a low-pressure barbecue may not stand up to the pressures of a commercial-grade grill or industrial-strength tools.

This consideration must be the muse of your decision-making course of.

Stress Score Issues

Correctly figuring out the strain score is important for security. A hose rated for decrease strain may rupture beneath greater working pressures, resulting in potential accidents. Seek the advice of the producer’s specs for the exact strain score of the hose and guarantee it aligns with the anticipated working strain of the tools. rule of thumb is to pick out a hose with a strain score that exceeds the anticipated working strain by an affordable margin, usually 10-20%.

Utility-Particular Necessities

Matching the hose to the applying is paramount. Elements akin to the kind of equipment, the frequency of use, and the working setting must be fastidiously thought-about. A hose appropriate for out of doors use in delicate climate may not be appropriate for harsh industrial situations or prolonged use in excessive temperatures. The meant use dictates the hose’s design and materials, straight impacting its sturdiness and security.

Key Questions for Evaluating Choices

Evaluating completely different fast join propane hose choices requires a structured strategy. Listed below are key inquiries to ask when making your choice:

- What’s the most working strain of the tools?

- What’s the meant use of the hose (e.g., residential, business, industrial)?

- What are the environmental situations the place the hose shall be used (e.g., temperature extremes, publicity to chemical substances)?

- What’s the anticipated lifespan and frequency of use?

- What’s the price range allotted for the hose?

These questions guarantee a radical analysis course of, stopping potential points down the road.

Receive a complete doc in regards to the software of how much does a chiropractor cost that’s efficient.

Model and Mannequin Comparability

A comparative evaluation of various manufacturers and fashions can support within the choice course of. This desk supplies a fundamental overview, however detailed specs ought to all the time be consulted straight from the producer’s web site.

| Model | Mannequin | Stress Score (PSI) | Materials | Value (USD) |

|---|---|---|---|---|

| Acme Propane | QC-1000 | 200 | Excessive-Density Polyethylene | $25 |

| Professional-Tech | QC-5000 | 300 | Stainless Metal Braided | $45 |

| MaxFlow | QC-7000 | 400 | Aluminum Strengthened | $60 |

Be aware that it is a simplified comparability and pricing might fluctuate primarily based on native market situations. All the time confirm specs with the producer for detailed data.

Visible Illustration

Understanding the visible points of a quick-connect propane hose is essential for protected and environment friendly use. Correct identification of parts and potential harm is vital to stopping accidents. A transparent visible information aids in right set up, upkeep, and troubleshooting.

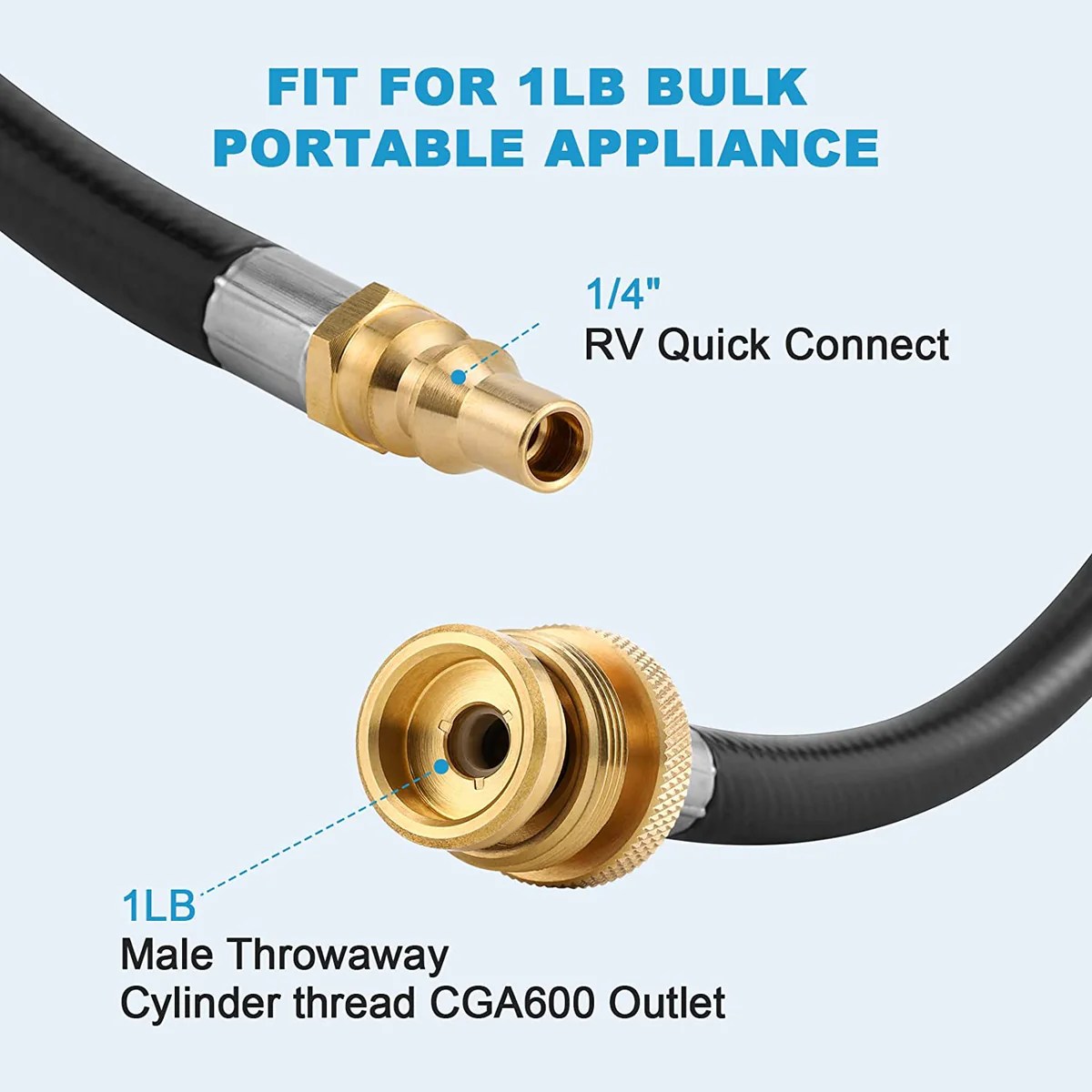

Fast Join Propane Hose Design

A fast-connect propane hose usually includes a sturdy, versatile hose physique constructed from sturdy supplies like bolstered nylon or artificial rubber. The hose’s exterior is usually coloured for straightforward identification, like a shiny orange or purple, and will have a protecting outer sheath. The ends of the hose are designed with quick-connect fittings, which often include a coupling mechanism.

This coupling mechanism is essential for securing the hose to the propane tank and equipment. A security collar may additionally be current to make sure the connection stays tight. The design is constructed for ease of connection and disconnection.

Connecting and Disconnecting the Hose

Correct connection and disconnection are important for security and stopping leaks. To attach the hose, align the quick-connect fittings on each ends. Make sure the fittings click on securely into place. Apply light, even strain till the connection is firmly established. To disconnect the hose, press the discharge lever on the quick-connect becoming and gently pull the hose aside.

Make sure the fittings are utterly separated earlier than transferring the hose.

Figuring out Broken Fast Join Propane Hose

Recognizing indicators of injury or compromise is essential for security. Search for cracks, tears, or punctures within the hose physique. Examine the quick-connect fittings for any indicators of damage or harm, akin to free or damaged components. Examine the hose for kinks, twists, or bends. A broken hose ought to by no means be used.

Correct Storage of Fast Join Propane Hose

Correct storage ensures the hose’s longevity and prevents harm. Retailer the hose in a cool, dry place away from direct daylight, excessive temperatures, and sharp objects. Keep away from storing the hose in areas vulnerable to moisture or chemical substances. Wrap the hose neatly and securely to forestall kinks and tangles. Retailer the hose individually from different gadgets that would trigger harm.

Fast Join Propane Hose Dimensions and Weights

The next desk supplies a comparability of dimensions and weights for various quick-connect propane hose fashions. Correct details about hose measurement and weight is important for correct choice and utilization.

| Mannequin | Size (ft) | Inside Diameter (in) | Weight (lbs) |

|---|---|---|---|

| QC-100 | 10 | 0.5 | 0.8 |

| QC-150 | 15 | 0.75 | 1.2 |

| QC-200 | 20 | 1.0 | 1.5 |

Remaining Abstract

In conclusion, fast join propane hoses supply vital advantages by way of effectivity, security, and comfort. Understanding the nuances of set up, upkeep, and security procedures is paramount. By meticulously following the rules and security protocols Artikeld on this information, you may guarantee easy operations and reduce potential dangers related to utilizing these hoses.

FAQ Useful resource

What are the frequent supplies utilized in fast join propane hoses?

Frequent supplies embrace high-strength metal, bolstered nylon, and varied forms of rubber or artificial polymers. The particular materials selection typically is determined by the meant use and strain scores.

What are some frequent issues with fast join propane hoses?

Frequent issues embrace leaks on the connections, harm to the hose itself, or points with the quick-connect fittings. Common upkeep and inspections can assist stop these issues.

What security tools is critical when utilizing fast join propane hoses?

Security glasses, gloves, and applicable private protecting tools (PPE) are essential for dealing with fast join propane hoses. All the time prioritize security when working with propane.

How do I select the best fast join propane hose for my software?

Think about the strain score, the working setting, and the particular software when choosing a fast join propane hose. All the time choose a hose that meets or exceeds the required strain score.