Oilless air compressor pump know-how is quickly evolving, providing a compelling various for varied purposes. From precision manufacturing to basic industrial use, these pumps are gaining traction attributable to their inherent benefits. Understanding the various varieties, purposes, and upkeep methods is essential for making knowledgeable choices.

This complete information delves into the intricacies of oilless air compressor pumps. We’ll discover differing kinds, their distinctive traits, and optimum purposes. The information additionally covers important upkeep procedures and troubleshooting suggestions to make sure long-term efficiency and reliability.

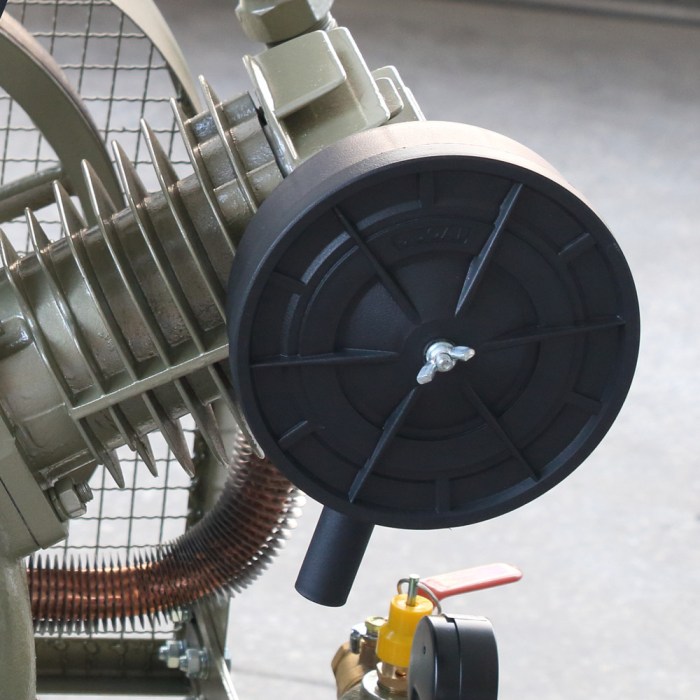

Varieties and Options of Oilless Air Compressor Pumps

Oilless air compressors are gaining traction in varied industries attributable to their inherent benefits over their oil-lubricated counterparts. These compressors provide a cleaner and extra environmentally pleasant operation, eliminating the necessity for oil modifications and lowering upkeep prices. Understanding the different sorts and their distinctive traits is essential for choosing the correct compressor for particular purposes.Oilless air compressors are available in varied designs, every with distinct options impacting efficiency and suitability.

Rotary vane, scroll, and piston compressors are frequent varieties, and every presents a novel steadiness of benefits and drawbacks. Selecting the suitable kind hinges on elements resembling required strain, stream fee, and the particular calls for of the appliance.

Rotary Vane Compressors

Rotary vane compressors make the most of rotating vanes inside a housing to compress the air. These vanes are guided by a hard and fast outer casing, making a progressively smaller quantity to extend strain. The simplicity of design usually interprets to a decrease preliminary value in comparison with different varieties.

- Simplicity of design contributes to decrease preliminary prices.

- Comparatively decrease upkeep necessities because of the absence of inner lubrication.

- Appropriate for reasonable strain and stream fee purposes.

- Could be noisy in comparison with different varieties.

- Effectivity will be decrease than scroll or piston compressors, notably at larger strain necessities.

Scroll Compressors

Scroll compressors make the most of two intermeshing helical scrolls to compress air. The scrolls’ progressive squeezing motion regularly reduces the amount, elevating the strain. They’re recognized for his or her clean operation and excessive effectivity, notably at medium to excessive stream charges.

- Excessive effectivity, particularly at medium to excessive stream charges.

- Quiet operation in comparison with different varieties.

- Usually, costlier than rotary vane compressors.

- Appropriate for purposes requiring constant excessive stream charges and medium strain.

- Extra complicated design in comparison with rotary vane, probably resulting in larger upkeep prices.

Piston Compressors

Piston compressors use reciprocating pistons to compress air inside cylinders. This design is extremely adaptable to a variety of strain and stream necessities. Nonetheless, they are often extra complicated and expensive to take care of in comparison with rotary vane or scroll compressors.

- Excessive strain functionality in comparison with rotary vane or scroll varieties.

- Excessive stream charges will be achieved, making them appropriate for demanding purposes.

- Extra complicated design and probably larger upkeep prices.

- Could be costlier than rotary vane compressors.

- Can generate extra noise in comparison with scroll compressors.

Comparability Desk

| Sort | Options | Advantages | Drawbacks | Purposes |

|---|---|---|---|---|

| Rotary Vane | Easy design, low preliminary value, low upkeep | Inexpensive, available | Decrease effectivity at larger pressures, will be noisy | Basic air instrument purposes, small-scale industrial wants |

| Scroll | Excessive effectivity, quiet operation, clean compression | Decreased vitality consumption, minimal noise | Greater preliminary value, potential upkeep complexity | Excessive-volume, high-quality air wants, delicate environments |

| Piston | Excessive strain functionality, excessive stream fee | Excessive strain output, high-volume output | Greater upkeep, extra complicated design | Heavy-duty purposes, industrial processes requiring excessive strain |

Purposes and Choice Standards for Oilless Air Compressors: Oilless Air Compressor Pump

Oilless air compressors are gaining traction throughout varied industries attributable to their inherent benefits, together with diminished upkeep and the elimination of oil contamination within the compressed air. Understanding the various purposes and essential choice standards is essential to optimizing effectivity and reaching desired outcomes. This detailed evaluation will assist you to navigate the choice course of, making certain the chosen compressor aligns seamlessly together with your particular wants.Oilless air compressors provide a compelling various to conventional oil-lubricated fashions, notably in delicate environments the place oil-free compressed air is paramount.

Components like the particular utility, required air quantity, strain, and funds will instantly affect the best compressor alternative. This complete information will equip you with the data to make knowledgeable choices, resulting in optimum efficiency and cost-effectiveness.

Numerous Industrial and Industrial Purposes

Oilless air compressors discover widespread use in varied industries. Their purposes span a spectrum of necessities, from exact manufacturing processes to general-purpose industrial duties. Pharmaceutical manufacturing, meals processing, and digital manufacturing are distinguished examples the place the elimination of oil contamination is crucial. Moreover, the rising adoption of automation in numerous sectors has created an growing demand for clear, dependable compressed air sources.

The inherent cleanliness of oilless compressors makes them well-suited for these fashionable industrial purposes.

Choice Standards for Oilless Air Compressors

A number of key elements ought to be thought-about when choosing an oilless air compressor for a specific utility. Cautious analysis of the compressor’s specs towards the appliance’s wants is important for reaching optimum efficiency. The required air quantity, strain, and working hours are essential preliminary issues. Budgetary constraints and the frequency of required upkeep also needs to be factored in.

Components Affecting the Choice Course of

A number of elements play a major function within the choice course of. The required air quantity, sometimes measured in cubic ft per minute (CFM), dictates the compressor’s measurement and capability. The specified strain, usually expressed in kilos per sq. inch (PSI), influences the compressor’s design and energy necessities. Working hours per day or week are important for calculating the compressor’s workload and the anticipated pressure on its elements.

The funds obtainable for the compressor buy and subsequent upkeep additionally considerably impacts the choice course of. Typically, a steadiness have to be struck between preliminary value and long-term operational effectivity. The frequency of upkeep required is one other very important side, as some compressors demand extra consideration than others.

Matching Compressor Specs to Utility Wants

A crucial side of the choice course of is making certain that the compressor’s specs exactly meet the calls for of the appliance. This requires cautious evaluation of the appliance’s wants, considering the required air quantity, strain, and working hours. A compressor that’s underpowered will wrestle to satisfy the required air quantity and strain, probably resulting in downtime and diminished productiveness.

Conversely, an outsized compressor will result in pointless bills and vitality waste.

Appropriate Oilless Air Compressor Varieties for Numerous Purposes, Oilless air compressor pump

| Utility | Required Strain (PSI) | Required Quantity (CFM) | Appropriate Pump Sort |

|---|---|---|---|

| Pneumatic Instruments (e.g., impression wrenches) | 90-120 | 2-5 | Rotary Screw |

| Portray and Coating | 80-100 | 10-15 | Rotary Screw |

| Welding | 90-150 | 5-10 | Rotary Screw |

| Packaging | 30-60 | 15-25 | Reciprocating |

| Basic Air Instruments | 50-80 | 3-8 | Reciprocating |

Upkeep and Troubleshooting of Oilless Air Compressor Pumps

Oilless air compressors, whereas providing the benefit of diminished upkeep and environmental impression in comparison with their oil-lubricated counterparts, nonetheless require cautious consideration to element for optimum efficiency and longevity. Correct upkeep and well timed troubleshooting can considerably prolong the lifespan of the compressor and decrease expensive repairs. This complete information will stroll you thru important preventive upkeep procedures and efficient troubleshooting steps for frequent points.Complete upkeep is essential to making sure clean operation, minimizing downtime, and lengthening the service lifetime of oilless air compressor pumps.

Ignoring preventative measures can result in expensive repairs and potential security hazards. The main focus right here is on proactive upkeep, enabling operators to foretell and tackle potential issues earlier than they escalate.

Preventive Upkeep Procedures

Preventive upkeep performs an important function in sustaining the effectivity and reliability of oilless air compressor pumps. A proactive strategy reduces the danger of surprising breakdowns and ensures constant efficiency. Common inspections and scheduled upkeep duties assist determine potential issues early on, permitting for well timed repairs and stopping important harm. Routine upkeep checks assist determine put on and tear, permitting for immediate repairs and stopping main failures.

- Recurrently examine the air compressor’s motor for any indicators of overheating, uncommon noises, or free connections. A visible inspection ought to be a part of any common preventative upkeep plan. Guarantee correct air flow across the motor to stop overheating.

- Clear the compressor’s air consumption filters and the compressor casing frequently. Contaminants within the air consumption can harm the interior elements, lowering effectivity and probably resulting in untimely put on. Common cleansing is essential for sustaining air high quality and compressor efficiency.

- Monitor the compressor’s strain readings to make sure they’re throughout the specified working vary. Variations in strain can point out points throughout the system. Constant strain monitoring may help determine and tackle issues early.

- Examine the compressor’s belts and pulleys for put on and tear. Unfastened or worn belts may cause vibrations and diminished effectivity. Recurrently examine the belts and pulleys for indicators of wear and tear, and exchange them as wanted to take care of optimum efficiency.

- Examine the compressor’s oil-free lubrication system for correct functioning. Lubrication points can result in elevated friction and element put on. Confirm correct lubrication and well timed replenishment (if required).

Troubleshooting Frequent Points

Troubleshooting points promptly can forestall main failures and guarantee steady operation. Figuring out and resolving issues rapidly is important to take care of productiveness and decrease downtime. A well-defined troubleshooting course of can rapidly isolate the foundation reason behind an issue.

| Downside | Potential Trigger | Resolution |

|---|---|---|

| Compressor not beginning | Defective electrical connections, tripped circuit breaker, or motor failure. | Examine electrical connections, reset circuit breaker, and seek the advice of a certified technician for motor diagnostics. |

| Low air strain | Blocked air filters, leaks within the system, or inadequate compressor capability. | Clear air filters, test for leaks, and make sure the compressor is satisfactorily sized for the appliance. |

| Excessive air temperature | Overloading the compressor, inadequate cooling, or a malfunctioning cooling system. | Cut back the load on the compressor, guarantee correct airflow, and test for points within the cooling system. |

| Uncommon noises | Unfastened elements, broken inner components, or worn bearings. | Examine for free components, exchange broken elements, and test bearing situation. |

| Compressor overheating | Inadequate cooling, overloading the compressor, or clogged air filters. | Enhance cooling, scale back load, clear filters, and tackle any blockage. |

Figuring out and Resolving Leaks

Leaks can result in diminished air output, decreased effectivity, and potential security hazards. Figuring out and repairing leaks promptly is essential for sustaining secure and environment friendly operation. An intensive inspection can reveal hidden leaks.

- Visible inspection of all connections and joints is important for detecting leaks. Examine hoses, fittings, and seals for any seen harm or indicators of leakage.

- Utilizing a leak detector may help pinpoint leaks that aren’t instantly seen. Using specialised instruments for detection will enhance accuracy.

- Addressing leaks promptly is significant to stop additional harm and preserve optimum efficiency. Change broken elements and seal any gaps to stop leaks.

Epilogue

In conclusion, oilless air compressor pumps current a compelling resolution for quite a few industrial and industrial wants. Their maintenance-friendly design and numerous purposes make them a precious asset. By understanding the varied varieties, choice standards, and upkeep methods, you possibly can confidently select the correct pump in your particular necessities. The important thing takeaway is matching the compressor’s specs to the appliance’s wants for optimum efficiency and longevity.

Query & Reply Hub

What are the frequent forms of oilless air compressors?

Frequent varieties embody rotary vane, scroll, and piston compressors. Every kind has its personal strengths and weaknesses when it comes to efficiency and utility.

What are the important thing choice standards for selecting an oilless air compressor?

Components like required air quantity, strain, funds, and upkeep wants ought to be thought-about. Matching the compressor’s specs to the appliance’s wants is essential.

What are some frequent upkeep procedures for oilless air compressors?

Common filter modifications, lubrication checks, and visible inspections are very important for optimum efficiency and longevity. Seek the advice of the producer’s suggestions for particular procedures.

What are some frequent troubleshooting steps for oilless air compressors?

Begin with primary checks like strain readings and filter situation. If issues persist, seek the advice of a certified technician.

What are the potential advantages of utilizing oilless air compressors?

Oilless air compressors provide a cleaner operation, lowering the danger of oil contamination within the compressed air. That is notably necessary in meals processing and pharmaceutical industries.