Ingersoll-Rand air compressor components PDF – a complete information to understanding, sustaining, and troubleshooting your gear. This useful resource dives deep into finding, figuring out, and changing components, providing sensible recommendation and beneficial insights for each novice and skilled customers. From detailed diagrams to troubleshooting ideas, this information empowers you to optimize your air compressor’s efficiency and longevity.

This in-depth information meticulously explores the intricacies of Ingersoll-Rand air compressor components. We’ll dissect catalogs, diagrams, and upkeep schedules to supply a transparent understanding of the varied elements, their features, and optimum alternative methods. Whether or not you might want to pinpoint a selected half or troubleshoot a standard concern, this complete information affords the data you might want to successfully handle your air compressor.

Ingersoll-Rand Air Compressor Elements Catalogs and Diagrams

Ingersoll-Rand air compressors are crucial items of kit in quite a few industries, from manufacturing to building. Sustaining these machines requires entry to correct and complete components data. This useful resource offers a deep dive into navigating Ingersoll-Rand’s components catalogs and diagrams, important for environment friendly repairs and optimum efficiency.

Complete Elements Listings by Mannequin Quantity

A vital facet of sustaining Ingersoll-Rand air compressors is having instant entry to the proper components. A well-organized components catalog is important, enabling technicians to find the exact elements wanted for restore or alternative. This catalog ought to categorize components by particular Ingersoll-Rand air compressor mannequin numbers. This enables for straightforward identification and ensures compatibility.

- Mannequin-specific listings present fast entry to all essential elements for every machine.

- Clear identification of components, together with element identify and half quantity, is important for correct ordering and set up.

- Detailed specs and dimensions for every half are crucial for correct match and performance.

Finding Particular Elements Utilizing Varied Search Standards

Discovering the fitting half shortly is essential for environment friendly upkeep. An efficient components catalog ought to enable for searches based mostly on numerous standards to streamline the method. These standards can embody half numbers, element names, purposes, and even descriptions.

- Search performance based mostly on half numbers permits for exact identification and retrieval.

- Search by element identify helps find components based mostly on their operate throughout the compressor.

- Looking out by utility permits for finding components appropriate for particular operational duties, corresponding to high-pressure or heavy-duty purposes.

Figuring out Suitable Elements Throughout Completely different Fashions

Figuring out compatibility between completely different Ingersoll-Rand air compressor fashions is a crucial facet of stock administration and repairs. This course of is simplified via detailed mannequin specs throughout the components catalog. Correct identification of appropriate elements reduces downtime and ensures the proper replacements.

Discovering Ingersoll-Rand air compressor components PDFs may be difficult, however a vital ingredient for upkeep is a dependable heavy obligation air hose reel. This important software, essential for environment friendly operation, can significantly influence the longevity of your Ingersoll-Rand compressor. A high-quality heavy duty air hose reel helps stop kinks and injury, guaranteeing the compressor features easily.

Correct upkeep, aided by detailed Ingersoll-Rand air compressor components PDFs, is vital to conserving your gear working optimally.

- Detailed mannequin specs throughout the catalog assist establish appropriate components.

- Cross-referencing of half numbers throughout numerous fashions streamlines the identification course of.

- Detailed diagrams and illustrations support in visible identification of appropriate elements.

Organized Elements Desk

A well-structured desk is invaluable for shortly referencing components data. This desk ought to set up components by mannequin, embody descriptions, half numbers, and ideally, pricing data. This desk needs to be simply accessible and searchable.

| Half Quantity | Description | Mannequin Quantity | Worth (USD) |

|---|---|---|---|

| 12345 | Air Filter | IRAC-1000 | $25.00 |

| 67890 | Compressor Piston | IRAC-2000 | $150.00 |

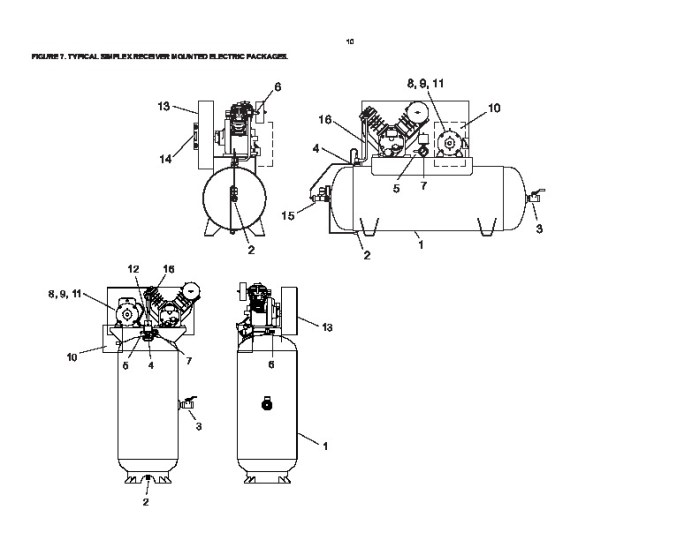

Illustrated Compressor Elements

Visible aids improve understanding of compressor elements and their purposes. Detailed illustrations or diagrams throughout the catalog assist technicians visualize the location and performance of every half throughout the general system. This aids in troubleshooting and restore.

Discovering Ingersoll-Rand air compressor components PDFs may be difficult, however a vital ingredient for upkeep is a dependable heavy obligation air hose reel. This important software, essential for environment friendly operation, can significantly influence the longevity of your Ingersoll-Rand compressor. A high-quality heavy duty air hose reel helps stop kinks and injury, guaranteeing the compressor features easily.

Correct upkeep, aided by detailed Ingersoll-Rand air compressor components PDFs, is vital to conserving your gear working optimally.

| Half Illustration | Half Title | Operate | Utility |

|---|---|---|---|

| (Picture of an air filter) | Air Filter | Removes impurities from the compressed air | Protects the compressor from injury and ensures clear compressed air |

| (Picture of a compressor piston) | Compressor Piston | Compresses the air | Drives the compression course of, crucial for producing stress |

Troubleshooting and Upkeep

Optimizing your Ingersoll-Rand air compressor’s efficiency depends closely on proactive troubleshooting and upkeep. A well-maintained compressor not solely extends its lifespan but in addition ensures constant output, minimizing downtime and operational prices. This part delves into widespread points, preventative upkeep, lubrication methods, and scheduling to maintain your compressor working easily.Understanding the interior workings of your air compressor, from the consumption valve to the discharge port, permits you to pinpoint issues effectively.

This understanding, mixed with a proactive upkeep schedule, is vital to avoiding expensive repairs and guaranteeing steady operation.

Frequent Air Compressor Points and Options

Correctly figuring out and addressing compressor issues is essential. This part Artikels widespread points and their corresponding options, emphasizing the significance of correct analysis. Incorrect analysis can result in pointless components alternative, growing your operational prices.

- Low Air Stress: Low air stress typically stems from points with the air filter, clogged consumption, or broken valves. Changing the air filter or cleansing the consumption system resolves this drawback. If valves are malfunctioning, a alternative is important.

- Excessive Working Temperature: Excessive working temperatures ceaselessly point out insufficient cooling or a malfunctioning cooling system. Examine the cooling fins for obstructions and guarantee correct airflow. A malfunctioning cooling fan or a broken radiator might have alternative.

- Uncommon Noises: Uncommon noises, corresponding to grinding or screeching sounds, normally point out points with bearings, free elements, or misaligned components. Examine the bearings for injury or extreme put on. Tightening free elements and correcting misalignments can typically resolve this.

- Leaks: Leaks within the air strains or compressor elements can result in decreased output and probably hazardous conditions. Examine all connections for leaks, utilizing soapy water to detect them. Substitute broken elements corresponding to hoses or fittings.

Preventative Upkeep Procedures

A proactive strategy to upkeep is important for maximizing compressor longevity and minimizing sudden downtime. Common preventative upkeep can stop expensive repairs and lengthen the operational lifetime of the compressor.

- Common Cleansing: Completely clear the compressor’s consumption and exhaust programs frequently to stop clogs. This contains cleansing the air filter, guaranteeing the consumption system is obvious of particles.

- Lubrication: Correct lubrication of shifting components is crucial. Observe the producer’s suggestions for lubricant sort and frequency. Common lubrication can considerably scale back put on and tear.

- Visible Inspections: Common visible inspections of all elements may also help establish potential issues early. Examine for any indicators of damage, injury, or leaks.

- Element Substitute: Substitute worn or broken elements as per the producer’s really useful schedule. This contains components like belts, hoses, and filters.

Significance of Correct Lubrication, Ingersoll-rand air compressor components pdf

Lubrication performs a vital position in minimizing friction and put on on crucial elements, instantly impacting the compressor’s lifespan. The proper lubricant selection and frequency are important.

- Bearing Safety: Correct lubrication protects compressor bearings from extreme put on, extending their lifespan.

- Lowered Friction: Lubrication minimizes friction between shifting components, resulting in smoother operation and diminished vitality consumption.

- Stopping Corrosion: Sure lubricants may assist stop corrosion in particular components.

Upkeep Schedules

A structured upkeep schedule based mostly on compressor mannequin and utilization frequency is essential for optimum efficiency. Seek the advice of the producer’s suggestions for particular schedules.

- Every day Checks: Every day checks ought to embody monitoring stress ranges, listening for uncommon noises, and visually inspecting for leaks.

- Weekly Inspections: Weekly inspections ought to embody cleansing the consumption filter and checking fluid ranges in lubrication programs.

- Month-to-month Upkeep: Month-to-month upkeep ought to embody an intensive cleansing of the compressor, checking belt stress, and lubrication of shifting components.

Frequent Issues and Options Desk

This desk offers a concise overview of widespread Ingersoll-Rand air compressor issues and their options, together with essential components replacements.

| Downside | Answer | Affected Elements |

|---|---|---|

| Low Air Stress | Substitute air filter, clear consumption system, substitute broken valves | Air filter, consumption system, valves |

| Excessive Working Temperature | Examine cooling fins, guarantee correct airflow, substitute cooling fan or radiator | Cooling fins, cooling fan, radiator |

| Uncommon Noises | Examine bearings for injury, tighten free elements, appropriate misalignments | Bearings, elements, alignment |

| Leaks | Examine connections, use soapy water to detect leaks, substitute broken hoses or fittings | Connections, hoses, fittings |

Substitute and Restore Info

Optimizing your Ingersoll-Rand air compressor’s lifespan hinges on well timed and correct repairs. Preventive upkeep is essential, however figuring out learn how to successfully substitute and restore elements when essential is equally important. This part offers detailed steering for these duties, emphasizing security and effectivity.Correct element alternative and restore procedures reduce downtime and guarantee optimum efficiency. This detailed data covers essential steps, security precautions, and value comparisons that will help you make knowledgeable selections.

Changing an Ingersoll-Rand Air Compressor Half

Thorough preparation is vital to a profitable half alternative. Make sure the compressor is shut down, the facility disconnected, and the air strains depressurized. This significant step prevents accidents and protects personnel. Discuss with the producer’s handbook for particular procedures.A vital facet of changing an element is knowing the exact process. Rigorously take away the previous half, following the steps Artikeld within the person handbook.

Discovering Ingersoll-Rand air compressor components PDFs may be difficult, however a vital ingredient for upkeep is a dependable heavy obligation air hose reel. This important software, essential for environment friendly operation, can significantly influence the longevity of your Ingersoll-Rand compressor. A high-quality heavy duty air hose reel helps stop kinks and injury, guaranteeing the compressor features easily.

Correct upkeep, aided by detailed Ingersoll-Rand air compressor components PDFs, is vital to conserving your gear working optimally.

Utilizing acceptable instruments and adhering to producer suggestions ensures the brand new half’s correct set up and performance.

Repairing Frequent Air Compressor Elements

Frequent points like worn piston rings or leaky valves necessitate repairs. This part particulars methods for repairing these elements.

Repairing Piston Rings

Step one in repairing piston rings includes inspecting them for put on and tear. Figuring out the extent of the injury is important for choosing the fitting restore technique. If the rings are severely worn, alternative is really useful. Nevertheless, if the wear and tear is minimal, a lapping course of can typically restore performance. This includes utilizing specialised instruments to clean the surfaces of the rings, lowering friction and bettering seal integrity.

Correct lubrication is essential for profitable ring restore.

Repairing Leaky Valves

Leaky valves could cause important air loss and diminished compressor effectivity. If the valve’s injury is minor, you would possibly be capable of restore it with a valve sealant. Nevertheless, if the injury is in depth, the valve might have to be changed. Once more, cautious adherence to producer’s directions is important for correct and protected valve restore.

Discovering Ingersoll-Rand air compressor components PDFs may be difficult, however a vital ingredient for upkeep is a dependable heavy obligation air hose reel. This important software, essential for environment friendly operation, can significantly influence the longevity of your Ingersoll-Rand compressor. A high-quality heavy duty air hose reel helps stop kinks and injury, guaranteeing the compressor features easily.

Correct upkeep, aided by detailed Ingersoll-Rand air compressor components PDFs, is vital to conserving your gear working optimally.

Comparability of Restore Strategies

Completely different restore strategies have various ranges of complexity and value. A comparability of those strategies, introduced beneath, permits for knowledgeable decision-making.

- Substitute: This technique usually includes buying a brand new half and putting in it in keeping with the producer’s directions. It typically leads to a whole restoration of the element’s performance, however the associated fee may be larger in comparison with different restore strategies.

- Restore: This strategy focuses on restoring the present half. It’d contain changing worn components, making use of sealants, or utilizing different corrective measures. This technique is normally cheaper than alternative however might not all the time obtain the identical degree of efficiency.

Instruments Required for Restore Procedures

The next desk categorizes the instruments wanted for numerous restore procedures.

Discovering Ingersoll-Rand air compressor components PDFs may be difficult, however understanding the upkeep wants of your gear is essential. For instance, in case your compressor wants servicing, take into account skilled air duct cleansing providers, like these supplied by air duct cleaning services grandin , to make sure optimum efficiency and lengthen the lifespan of your gear. Complete documentation, like Ingersoll-Rand air compressor components PDFs, is important for efficient troubleshooting and restore.

| Process | Instruments Required |

|---|---|

| Piston Ring Restore | Ring lapping software, piston ring units, cleansing solvents |

| Valve Restore | Valve sealant, valve wrenches, cleansing solvents |

| Common Compressor Upkeep | Torque wrenches, screwdrivers, adjustable wrenches |

Value Comparability of Substitute Elements

The desk beneath compares the price of alternative components from completely different distributors. Contemplate elements like guarantee and vendor popularity when making your buy choice.

| Vendor | Half Quantity | Worth |

|---|---|---|

| Vendor A | XYZ123 | $150 |

| Vendor B | XYZ123 | $125 |

| Vendor C | XYZ123 | $175 |

Closing Abstract: Ingersoll-rand Air Compressor Elements Pdf

In conclusion, mastering your Ingersoll-Rand air compressor includes a mix of meticulous analysis, proactive upkeep, and a eager understanding of alternative methods. This information offers the roadmap for navigating the complexities of your gear. Armed with this information, you possibly can guarantee peak efficiency, prolonged lifespan, and in the end, a big return in your funding. The wealth of knowledge introduced will show invaluable in optimizing your operation and sustaining optimum effectivity.

Query & Reply Hub

What are the commonest air compressor points?

Frequent points embody leaks, low air stress, and motor issues. This information offers detailed troubleshooting steps to diagnose and resolve these points.

How can I decide if an element is appropriate with my Ingersoll-Rand mannequin?

The information contains strategies for figuring out appropriate components based mostly on mannequin numbers and element descriptions, guaranteeing correct replacements.

The place can I discover pricing data for Ingersoll-Rand components?

Whereas an entire value record is not included, the information suggests evaluating costs from completely different distributors for knowledgeable buying selections.

What security precautions ought to I take when changing components?

The information emphasizes the significance of security precautions, together with correct dealing with and use of security gear throughout any restore or alternative process.

What instruments are required for various restore procedures?

A categorized record of instruments, related to particular duties, is included that will help you put together for any restore or upkeep venture.