Gasoline air compressor mills are important instruments for quite a lot of functions, from powering development websites to offering backup energy for houses. Understanding their differing types, choosing the correct one in your wants, and guaranteeing correct upkeep are essential for maximizing their effectivity and longevity. This information delves into the world of fuel air compressor mills, exploring their capabilities, widespread makes use of, and important upkeep procedures that can assist you make knowledgeable choices.

From transportable models good for smaller tasks to industrial-grade fashions able to dealing with large workloads, this complete overview will information you thru the essential elements to contemplate when selecting the perfect fuel air compressor generator. We’ll additionally cowl essential features like gas effectivity, upkeep, and security issues.

Gasoline Air Compressor Turbines

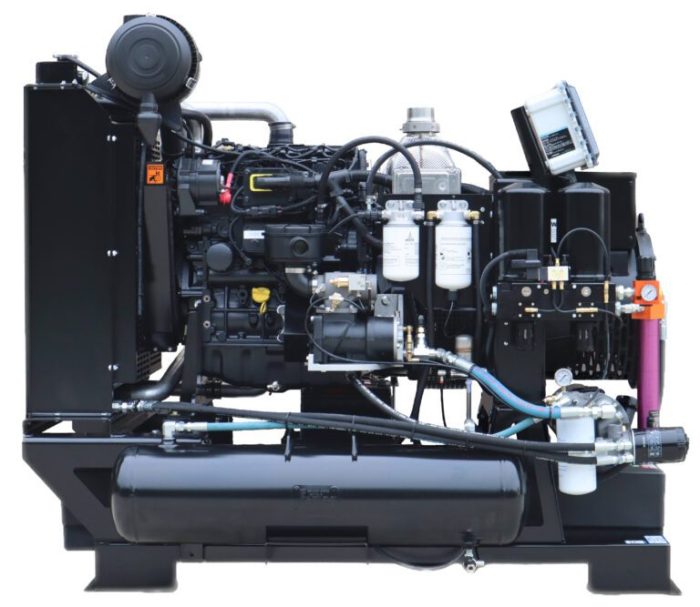

Gasoline air compressor mills are versatile energy sources, combining the performance of a compressor and a generator. They supply compressed air for varied industrial duties and backup energy when wanted. Their adaptability makes them helpful instruments in various settings, from development websites to distant areas.Gasoline air compressor mills are subtle machines with interconnected elements that ship each compressed air and electrical energy.

A key aspect is the engine, which might be fueled by varied sources like propane, pure fuel, or diesel. This engine powers the compressor, which then generates the compressed air. {The electrical} generator, additionally pushed by the engine, produces the mandatory electrical energy. The general design permits for a seamless transition between air compression and energy era.

Varieties of Gasoline Air Compressor Turbines

Gasoline air compressor mills can be found in quite a lot of configurations, every designed for particular wants. Moveable fashions are light-weight and simply transported, making them superb for momentary or cell functions. These mills are generally present in development, occasion setups, and upkeep work. Industrial fashions, alternatively, are extra strong and have greater energy outputs.

They’re generally utilized in manufacturing services, massive development tasks, and different demanding environments. Specialty mills are tailor-made for particular functions, like these requiring extraordinarily high-pressure air or tailor-made energy outputs.

Gasoline air compressor mills are essential for varied industrial functions, particularly when precision is essential. Their constant output is significant for duties like scorching air welding plastic, a specialised approach demanding dependable and controlled warmth. Optimizing the fuel air compressor generator’s efficiency is essential for achievement in any utility, together with advanced tasks involving hot air welding plastic.

Correct upkeep and choice are important for dependable operation in demanding environments.

Functions of Gasoline Air Compressor Turbines

Gasoline air compressor mills are extensively utilized throughout quite a few industries. In development, they’re important for powering pneumatic instruments like jackhammers and nail weapons. They supply a dependable supply of compressed air and electrical energy for varied duties, reminiscent of inflating tires and working lights. In manufacturing, these mills are essential for sustaining manufacturing strains and working tools.

Gasoline air compressor mills are essential for varied industrial functions. Their effectivity typically hinges on the standard of the air supply system, which frequently features a spiral air duct machine. A well-designed spiral air duct machine ensures optimum air movement and strain, finally maximizing the fuel air compressor generator’s output. That is essential for constant efficiency and long-term reliability.

They guarantee constant air strain for equipment, whereas additionally providing backup energy for essential operations. Moreover, they’re typically employed in emergency conditions, supplying energy and compressed air to hospitals, communication facilities, and different important services.

Environmental Impression

The environmental impression of fuel air compressor mills is a big consideration. Emissions from the engine, primarily carbon dioxide and different pollution, can contribute to air high quality points. The noise generated throughout operation may impression the encircling atmosphere. Noise ranges differ relying on the mannequin and working situations, and sometimes exceed acceptable limits for residential areas.

Gasoline air compressor mills are essential for varied duties, from powering development websites to offering backup energy. Nonetheless, restoring a traditional automotive like a 1957 Chevy Bel Air body 1957 chevy bel air frame typically requires specialised instruments and tools, together with high-quality, dependable air compressors for varied duties, making them important for a complete restoration course of.

Optimizing the generator in your restoration venture is essential to a profitable end result.

Comparability of Gasoline Air Compressor Generator Varieties

| Kind | Energy Output (HP) | Gasoline Effectivity (L/hr) | Upkeep |

|---|---|---|---|

| Moveable | 5-25 HP | 2-8 L/hr | Comparatively low; simply accessible elements |

| Industrial | 25-100+ HP | 8-30+ L/hr | Larger upkeep attributable to bigger elements; doubtlessly specialised mechanics |

Be aware: The desk offers normal estimations. Precise values might differ based mostly on particular fashions and working situations. Gasoline effectivity figures are influenced by elements reminiscent of engine load, gas sort, and working temperature.

Choosing the Proper Gasoline Air Compressor Generator

Selecting the best fuel air compressor generator is essential for guaranteeing environment friendly and dependable operation. It entails a cautious analysis of assorted elements, together with energy necessities, gas sort, and potential upkeep wants. A poorly chosen generator can result in underperformance, pricey repairs, and security hazards. Conversely, a well-matched generator will contribute to easy operations and long-term cost-effectiveness.Matching the generator’s output to the precise wants of the applying is paramount.

This entails understanding the required air strain and quantity for the meant duties. Ignoring these elements can result in insufficient efficiency or, in some instances, even injury to the tools being powered. The generator’s capability ought to be enough to deal with the height demand, guaranteeing constant efficiency even beneath heavy masses.

Energy Output and Air Necessities

The ability output of the generator is a essential issue. It should meet the mixed calls for of the compressor and some other tools related to the system. Inadequate energy will end in insufficient air strain or quantity, impacting productiveness. Conversely, extreme energy is wasteful and will increase working prices. Thorough evaluation of the required air strain and quantity is crucial for correct sizing.

Gasoline air compressor mills are essential for varied energy instruments, together with these used for smoothing and ending duties. Selecting the best energy instrument, like an air sander versus an electrical sander, considerably impacts effectivity and outcomes. As an example, understanding the professionals and cons of every instrument, particularly when evaluating air sander vs electric sander choices, can optimize your workflow and save time.

Finally, a fuel air compressor generator is usually a highly effective asset for any venture requiring precision and management.

Gasoline Kind Issues, Gasoline air compressor generator

Completely different gas sorts supply various efficiency traits. Propane, for instance, is usually most well-liked for its portability and ease of use, whereas pure fuel is perhaps less expensive in sure areas. Diesel, although typically a extra highly effective possibility, comes with its personal set of upkeep necessities. The number of gas sort will depend on elements reminiscent of native gas availability and value, environmental issues, and the precise wants of the applying.

Questions for Potential Suppliers

To make sure the chosen generator meets the precise necessities, it is important to ask potential suppliers pertinent questions. These questions ought to cowl features just like the generator’s energy output, gas effectivity, upkeep schedules, and guarantee particulars. This course of permits for a complete analysis of the generator’s suitability and helps to keep away from potential points afterward. A guidelines of key questions is crucial.

- What’s the generator’s most energy output, and what’s its gas consumption charge at completely different masses?

- What are the generator’s beginning torque and run time on a full tank of gas?

- What are the upkeep necessities and related prices?

- What are the guarantee phrases and repair agreements?

- Does the provider supply coaching or assist providers for working and sustaining the generator?

Energy Requirement and Generator Varieties

Matching the proper generator sort to the precise energy necessities is essential for optimum efficiency. The desk under Artikels appropriate generator sorts for varied energy necessities, highlighting key options of every. This desk aids in fast choice based mostly on the facility wants of the applying.

| Energy Requirement (kW) | Appropriate Generator Kind | Options |

|---|---|---|

| 5 kW | Moveable Gasoline Generator | Light-weight, straightforward to maneuver, appropriate for smaller tasks. |

| 10 kW | Moveable Diesel Generator | Larger energy output, appropriate for bigger tasks or a number of air compressors. |

| 20 kW | Stand-alone Diesel Generator | Excessive-power output, appropriate for heavy-duty industrial use. |

Upkeep and Operation of Gasoline Air Compressor Turbines

Correct upkeep and operation are essential for the longevity and environment friendly efficiency of fuel air compressor mills. Neglecting these features can result in pricey repairs, lowered output, and even security hazards. This part delves into the important steps for sustaining and working these essential items of kit.Gasoline air compressor mills are advanced machines requiring consideration to element in each their each day operation and scheduled upkeep.

Understanding the intricacies of those techniques is essential to maximizing their lifespan and output. By following the rules introduced, customers can mitigate potential points and make sure the generator features optimally.

Important Upkeep Steps

Common upkeep is significant for stopping pricey repairs and guaranteeing the generator operates at peak efficiency. Preventive upkeep procedures kind the bedrock of long-term reliability.

- Gasoline Checks: Frequently examine gas ranges and make sure the gas tank is clear and freed from contaminants. This helps stop clogs and ensures correct combustion.

- Oil Modifications: Altering the engine oil on the advisable intervals is essential. Soiled oil can result in untimely put on and tear on engine elements, decreasing the generator’s lifespan and doubtlessly inflicting important injury. Use the producer’s specified oil sort and alter intervals.

- Filter Replacements: Air filters, gas filters, and oil filters play a essential position in sustaining the generator’s effectivity. Clogged filters prohibit airflow and gas movement, decreasing efficiency and growing put on on elements. Observe the producer’s suggestions for filter substitute intervals.

- Part Inspections: Visible inspections of belts, hoses, and connections are important. Search for indicators of damage, injury, or looseness. Promptly tackle any points to stop potential breakdowns.

Working Procedures

Protected and environment friendly operation is paramount. Following correct procedures minimizes the danger of accidents and ensures optimum output.

- Begin-up Checks: Earlier than beginning the generator, confirm that every one security options are engaged, gas ranges are sufficient, and the load is correctly related.

- Operational Monitoring: Continually monitor the generator’s efficiency indicators, together with engine temperature, oil strain, and air strain output. Pay shut consideration to any uncommon noises or vibrations.

- Load Administration: Make sure that the generator will not be overloaded past its capability. Overloading can injury the engine and scale back the generator’s lifespan.

- Shutdown Procedures: Observe the producer’s pointers for safely shutting down the generator. Enable the engine to chill down earlier than disconnecting any tools.

Troubleshooting Frequent Issues

Troubleshooting points is an integral a part of proudly owning and working any tools.

- Low Air Strain: Test for leaks within the air strains, clogged filters, or insufficient air movement. Make sure the generator is correctly lubricated.

- Engine Overheating: Look at the coolant ranges, guarantee correct air flow, and determine any obstructions affecting airflow. If overheating persists, instantly shut down the generator.

- Noisy Operation: Pay attention fastidiously for uncommon sounds. These might point out a free element, worn elements, or a mechanical downside requiring quick consideration.

Significance of Common Upkeep

Common upkeep is greater than only a good observe; it is a essential funding. A well-maintained generator can have an extended lifespan, function extra effectively, and scale back the danger of breakdowns.

Gasoline air compressor mills are essential for varied duties, particularly when needing constant air strain. A key utility entails powering a coil air nailer gun, like this one , for environment friendly fastening. Finally, the correct fuel air compressor generator choice ensures dependable efficiency in your tasks.

- Diminished Restore Prices: Proactive upkeep minimizes the necessity for pricey repairs and replacements.

- Improved Efficiency: Properly-maintained mills ship constant and dependable efficiency.

- Enhanced Security: Common inspections be certain that security options are functioning appropriately.

Security Precautions

Security ought to all the time be a prime precedence when dealing with and working fuel air compressor mills. Observe these pointers for a safe and productive expertise.

- Air flow: Guarantee correct air flow within the working space to stop the buildup of dangerous fumes.

- Private Protecting Tools (PPE): All the time put on acceptable PPE, together with eye safety, gloves, and ear safety, when working across the generator.

- Clearance: Preserve a secure distance from the generator and any potential hazards throughout operation.

Final result Abstract

In conclusion, choosing the proper fuel air compressor generator will depend on cautious consideration of your particular wants, finances, and environmental impression. By understanding the differing types, energy necessities, and upkeep schedules, you’ll be able to choose a generator that successfully meets your calls for whereas prioritizing security and longevity. Correct upkeep, as Artikeld on this information, is essential to optimizing efficiency and increasing the lifespan of your funding.

FAQ Insights

What are the standard noise ranges of various fuel air compressor generator sorts?

Noise ranges differ considerably relying on the scale and mannequin of the generator. Moveable models are usually louder than industrial fashions. Think about noise ranges when selecting a generator in your particular location and work atmosphere.

How do I decide the proper energy output for my wants?

Rigorously assess the air strain and quantity necessities of your utility. Utilizing a calculator or consulting with a provider can assist make sure the generator’s energy output meets your particular wants. Overestimating is usually higher than underestimating energy necessities.

What are some widespread troubleshooting steps for fuel air compressor mills?

Frequent points embrace low gas strain, insufficient oil ranges, or clogged filters. Checking the gas, oil, and air filters, in addition to inspecting hoses and connections, are important first steps in troubleshooting.

What are the important thing variations between gasoline and propane mills for air compressors?

Gasoline is a extra available gas, whereas propane mills can typically supply barely higher gas effectivity. Think about elements like gas availability, price, and environmental impression when making your resolution.