Air dryer filter for compressor: A essential element usually missed, but very important for optimum compressor efficiency and longevity. This in-depth information delves into the performance, upkeep, and collection of these important filters, offering actionable insights for professionals and DIY fanatics alike. Understanding the intricacies of air dryer filters is essential to maximizing your compressor’s effectivity and lifespan.

From detailed explanations of various filter sorts and their filtration efficiencies to step-by-step upkeep procedures and a complete choice information, this useful resource empowers you to make knowledgeable choices. Selecting the best air dryer filter to your compressor can dramatically impression its efficiency and operational price.

Air Dryer Filter Performance

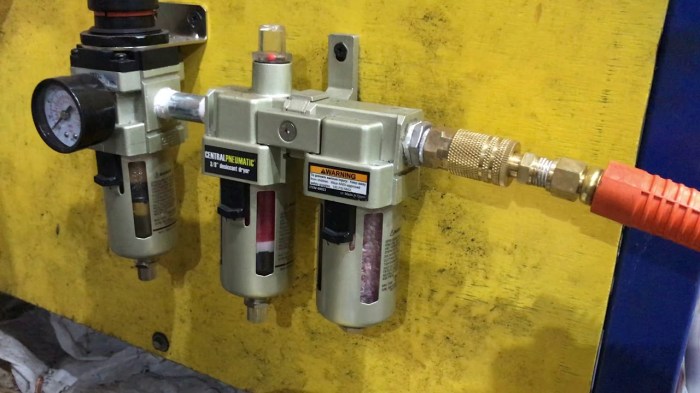

Compressed air methods are very important in quite a few industries, from manufacturing to automotive restore. Sustaining optimum air high quality is essential for the effectivity and longevity of those methods. A essential element on this course of is the air dryer filter. This filter performs a pivotal position in making certain that the compressed air delivered is free from moisture and contaminants.

This, in flip, prevents pricey tools harm and extends the lifetime of all the system.The air dryer filter is a specialised element designed to take away moisture and particulate matter from compressed air. This course of is crucial to guard downstream tools from corrosion, malfunction, and untimely put on. The filter’s efficacy hinges on its potential to entice and retain these contaminants, permitting clear, dry air to cross by.

A well-maintained filter is key to the sleek operation of any compressor system.

A clogged or soiled air dryer filter to your compressor can result in compressor points, doubtlessly inflicting a build-up of contaminants. This could typically manifest as a fuel scent emanating from air vents in your own home, as seen in conditions like gas smell from air vents in house. Often changing or cleansing your air dryer filter is essential to keep up optimum compressor efficiency and keep away from potential security hazards.

Perform of an Air Dryer Filter

The first perform of an air dryer filter is to take away moisture and contaminants from compressed air. This course of is significant to the compressor system’s general effectivity and longevity. The filter acts as a barrier, trapping water droplets, oil particles, and different impurities that may trigger vital issues in downstream purposes. Efficient filtration prevents corrosion, reduces put on on elements, and maintains the integrity of the compressed air system.

Sustaining optimum air high quality in your compressor system is essential, particularly when utilizing instruments just like the Stanley Bostitch air staple gun. A clear air dryer filter prevents clogs and ensures constant energy, in the end maximizing the lifespan of your tools. Correct upkeep of your air dryer filter is a essential step in retaining your complete system operating easily.

Kinds of Air Dryer Filters and Their Functionalities

Numerous sorts of air dryer filters can be found, every with particular functionalities. These embody:

- Coarse filters: These filters are the preliminary line of protection, eradicating bigger particles comparable to mud, filth, and particles. Their position is to guard extra delicate downstream filters and elements from untimely put on and tear. This pre-filtration step considerably improves the general effectivity of all the system.

- Nice filters: These filters goal smaller contaminants, comparable to microscopic particles and oil aerosols. They’re essential in eradicating contaminants that may be dangerous to downstream tools. By eradicating these fantastic particles, fantastic filters improve the air high quality, stopping potential harm and bettering efficiency.

- Membrane filters: These filters make the most of a specialised membrane to take away moisture and contaminants. Their potential to take away moisture makes them notably appropriate for purposes requiring extraordinarily dry compressed air. The membrane’s construction permits for environment friendly filtration whereas minimizing stress drop.

Affect of a Clear Air Dryer Filter on Compressor Efficiency

A clear air dryer filter is crucial for optimum compressor efficiency. A correctly functioning filter ensures that the compressed air delivered is free from moisture and contaminants, thereby stopping points comparable to corrosion, tools harm, and untimely element failure. The result’s a major improve in effectivity, decreased downtime, and prolonged lifespan for all the compressor system.

Results of a Clogged or Broken Air Dryer Filter on Compressor Efficiency

A clogged or broken air dryer filter can severely impression compressor efficiency. Clogged filters limit airflow, resulting in elevated stress drop throughout the system. This decreased airflow could cause the compressor to work tougher, consuming extra vitality and doubtlessly resulting in overheating. Broken filters might permit contaminants to bypass the filtration course of, resulting in system harm and decreased output.

The implications of a compromised filter might be substantial, starting from decreased output to vital tools failures.

Comparability of Filter Varieties

The desk under offers a comparability of various filter sorts, supplies, and filtration efficiencies. The information introduced highlights the various choices obtainable and their respective efficiency traits. Selecting the suitable filter sort relies on the precise wants and software.

Optimizing your air dryer filter for compressor efficiency is essential. A key issue to contemplate is how your chosen filter impacts downstream tools, like an air cleaner 4 barrel, which can be found here. In the end, a well-maintained air dryer filter is crucial for constant, high-quality compressed air, resulting in improved productiveness and decreased upkeep prices.

| Filter Kind | Materials | Filtration Effectivity (%) | Price |

|---|---|---|---|

| Coarse Filter | Polyester, Polypropylene | 70-90 | Low |

| Nice Filter | Metallic Mesh, Cellulose | 95-99 | Medium |

| Membrane Filter | Polytetrafluoroethylene (PTFE) | 99.9+ | Excessive |

Upkeep and Substitute: Air Dryer Filter For Compressor

Correct upkeep of an air dryer filter is essential for the longevity of your compressor system. Neglecting filter upkeep can result in decreased efficiency, elevated vitality consumption, and in the end, pricey repairs. A clear filter ensures optimum air high quality, stopping contamination and harm to downstream tools.Sustaining a clear and useful air dryer filter is paramount to the effectivity and reliability of your compressor.

This contains not solely common cleansing but additionally understanding the indicators of a compromised filter and understanding when substitute is important. By adhering to a constant upkeep schedule, you may safeguard your funding and forestall pricey downtime.

Correct Cleansing Procedures

Common cleansing of the air dryer filter is crucial to stop clogging and preserve optimum efficiency. Use compressed air or a brush to dislodge any collected particles. Keep away from utilizing harsh chemical compounds or abrasive supplies, as these can harm the filter’s construction. Make sure the filter is completely dry earlier than reinstalling it.

Figuring out Indicators of a Clogged or Broken Filter, Air dryer filter for compressor

A number of indicators recommend a clogged or broken filter. Decreased airflow, noticeable stress drop within the system, and strange noises throughout operation are all potential warning indicators. Moreover, test the filter’s bodily situation for tears, holes, or extreme buildup of contaminants. A visually compromised filter might require instant substitute.

Frequency of Filter Substitute

The frequency of filter substitute relies on a number of elements, together with the working circumstances of the compressor and the environmental contaminants current. Extra frequent substitute could also be needed in dusty environments or high-usage purposes.

Significance of Common Upkeep for Compressor Longevity

Common filter upkeep is significant for preserving the lifespan of your compressor. A clogged or broken filter could cause untimely put on and tear on the compressor elements. This could result in pricey repairs, prolonged downtime, and doubtlessly compromise the general reliability of all the system.

Step-by-Step Filter Substitute Information

Comply with these steps for a protected and environment friendly filter substitute:

- Flip off the compressor and disconnect the ability provide.

- Fastidiously drain any remaining compressed air from the system.

- Find and detach the air dryer filter meeting.

- Totally clear the filter and the encircling space.

- Set up the brand new filter making certain correct alignment.

- Reconnect the ability provide and switch the compressor again on.

Security Precautions

Prioritize security throughout filter substitute. All the time disconnect the ability provide to stop electrical hazards. Make sure the compressor system is depressurized to remove the chance of unintentional discharge of compressed air. Use acceptable security gear, comparable to gloves and eye safety, to mitigate potential dangers.

A clogged air dryer filter to your compressor can result in varied points, together with efficiency issues. This could usually manifest in an out of doors air con unit not operating here , making it essential to recurrently test and change the filter. Addressing this filter situation promptly can stop extra vital and expensive repairs down the road.

Instruments Wanted for Filter Substitute

The instruments required for filter substitute usually embody a wrench, screwdriver, and compressed air. Particular instruments may differ relying on the compressor mannequin.

Filter Substitute Schedules

| Working Situations | Frequency of Substitute | Clarification |

|---|---|---|

| Clear, low-dust setting, rare use | Each 6 months | Common cleansing might suffice, however scheduled substitute is really useful. |

| Dusty setting, average use | Each 3 months | Frequent cleansing and substitute are needed to keep up air high quality. |

| Excessive-dust setting, heavy use | Month-to-month | Excessive contaminant ranges necessitate extra frequent replacements to stop clogging. |

Filter Choice and Affect

Choosing the suitable air dryer filter to your compressor is essential for sustaining optimum compressed air high quality and lengthening the lifespan of your tools. Selecting the flawed filter can result in decreased effectivity, untimely element failure, and even security hazards. Understanding the elements influencing filter choice and the impression of various filter sorts is paramount.The efficiency of your compressed air system is intrinsically linked to the air dryer filter.

A poorly chosen filter can compromise the drying course of, resulting in moisture buildup and potential harm to downstream tools. Conversely, a well-chosen filter ensures environment friendly drying, maximizing system reliability and productiveness.

Components to Think about When Choosing a Filter

Correct filter choice relies on a number of key elements. Matching the filter’s specs to your compressor’s drying capability is paramount. Think about the ambient circumstances the place the compressor operates. Excessive humidity environments necessitate filters able to dealing with larger moisture hundreds. Moreover, the kind of compressed air software considerably influences filter choice.

Industrial portray requires totally different filtration traits than pneumatic instruments.

Filter Materials Comparability

Totally different filter supplies provide various ranges of efficiency. Activated carbon filters excel at eradicating odor-causing contaminants. Artificial media filters, like cellulose, are steadily used for general-purpose purposes. Porous ceramic filters usually provide superior filtration effectivity and can be utilized for high-pressure purposes. The collection of materials relies on the precise contaminants and desired stage of filtration.

Sustaining optimum air compressor efficiency hinges on a clear air dryer filter. This essential element straight impacts the standard of compressed air. For enhanced safety, think about upgrading to a high-quality sportster air filter cowl, just like the one obtainable at sportster air filter cover , to defend the filter from particles. This proactive measure will prolong the lifespan of your air dryer filter and guarantee constant, high-quality output out of your compressor.

Matching Filter to Compressor Drying Capability

Matching the filter’s capability to the compressor’s air drying capability is essential. Outsized filters are sometimes pointless and might result in decreased airflow. Undersized filters cannot adequately take away moisture, leading to diminished efficiency. Think about your compressor’s dew level specification when choosing the filter. A filter that can’t obtain the required dew level will compromise the drying course of.

Affect on Compressed Air High quality

The kind of filter straight impacts the standard of compressed air. Filters with finer pore sizes typically provide larger filtration effectivity, eradicating extra contaminants and leading to cleaner, drier air. This cleaner air improves the efficiency of downstream tools, extends their lifespan, and minimizes the chance of apparatus harm. Utilizing filters particularly designed for the elimination of oil or different particular contaminants is crucial for sure purposes.

Excessive-Effectivity Filters

Excessive-efficiency filters, usually using a number of filtration levels or superior supplies, present superior contaminant elimination. These filters can take away a broader vary of contaminants, bettering the standard of compressed air, extending the lifetime of downstream tools, and enhancing security. Nonetheless, high-efficiency filters may end in barely larger stress drops in comparison with normal filters.

Filter Model Efficiency Comparability

| Model | Filter Kind | Efficiency (Dew Level Discount) | Evaluations |

|---|---|---|---|

| FilterCo | Activated Carbon/Cellulose | 30°C | Excessive buyer satisfaction with dependable efficiency |

| DryAir Options | Ceramic/Artificial | 10°C | Constructive suggestions on sturdiness and effectivity in high-pressure environments |

| PureAir Applied sciences | Multi-stage/Membrane | 5°C | Glorious critiques for superior moisture elimination in demanding purposes |

Epilogue

In conclusion, sustaining your compressor’s air dryer filter is not only a finest observe; it is a necessity for sustained efficiency and longevity. By understanding the performance, upkeep necessities, and choice standards, you may considerably enhance your compressor’s effectivity and decrease pricey repairs. This information offers a complete useful resource that can assist you make knowledgeable choices about your air dryer filter and hold your compressor operating easily.

FAQ Part

What are the widespread causes of compressor failure?

A number of elements can contribute to compressor failure, together with insufficient upkeep, incorrect filter choice, and improper working circumstances. Understanding these potential points is essential for proactive upkeep.

How usually ought to I change the air dryer filter?

The frequency of filter substitute relies on elements like utilization depth, environmental circumstances, and the filter’s design. Seek the advice of the producer’s suggestions or check with the offered tables for particular pointers.

What are the indicators of a clogged or broken air dryer filter?

Decreased airflow, elevated compressor noise, and decreased efficiency are widespread indicators of a clogged or broken filter. Common inspection and immediate substitute are key to avoiding extra severe issues.

What are the important thing elements to contemplate when choosing an air dryer filter?

Components to contemplate embody the compressor’s air drying capability, the filter’s materials and filtration effectivity, and compatibility along with your particular software. Thorough analysis and cautious consideration are important.