Air conditioner PCB board malfunctions can result in expensive repairs and irritating downtime. Understanding the intricacies of those boards, from troubleshooting widespread points to mastering design ideas, is essential for each technicians and engineers. This information delves deep into the world of air conditioner PCB boards, overlaying every part from diagnosing failures to optimizing design selections.

From figuring out the telltale indicators of a failing part to choosing the proper PCB supplies for optimum efficiency, this complete useful resource supplies a roadmap for anybody working with air conditioner techniques. We’ll dissect widespread failure modes, look at important design issues, and analyze the essential elements that make these boards tick.

Air Conditioner PCB Board Troubleshooting

Diagnosing points with air conditioner PCB boards requires a scientific method. Understanding the everyday failure modes and their causes is essential for efficient troubleshooting. Correct identification of the issue usually results in quicker and extra correct repairs, minimizing downtime and prices. A methodical method, using acceptable diagnostic instruments, is essential to profitable repairs.Air conditioner PCB boards, regardless of their compact measurement, management a fancy interaction of elements.

Malfunctions can manifest in numerous methods, affecting cooling effectivity, fan operation, and temperature regulation. A radical understanding of those points is important for efficient repairs.

Frequent Air Conditioner PCB Board Failure Modes

Understanding the various vary of signs related to PCB board failures is significant for correct analysis. This part Artikels widespread failure modes, categorized by the observable symptom.

Troubleshooting air conditioner PCB boards usually includes understanding the underlying electrical techniques. A deep dive into associated instruments and gear, such because the craftsman 150 psi air compressor manual , can provide precious insights for diagnosing particular points. Finally, a scientific method to analyzing the PCB board’s performance is essential to efficient repairs.

- No Energy: This means a possible downside with the facility provide part of the PCB. Attainable causes embody defective capacitors, diodes, or the facility transformer itself. Environmental elements, comparable to excessive temperature fluctuations, may also influence energy provide reliability.

- Fan Not Working: A non-functional fan might be attributable to a failed motor management circuit, a defective fan motor, or an issue with the wiring connecting the fan to the PCB. Issues with the fan motor itself or free connections throughout the fan meeting may also result in this symptom.

- Erratic Temperature Management: This symptom suggests points throughout the temperature management circuit. Potential causes embody defective sensors, a broken microcontroller, or incorrect calibration of the management system. Inaccurate readings from the temperature sensors may also result in erratic management habits.

- Biking Points: Repeated on-off cycles, with out reaching the specified temperature, usually point out a malfunction within the temperature management loop. Attainable causes embody defective thermistors, issues with the management logic, or an issue with the cooling system itself. If the unit is biking too often, it will possibly point out a blockage or restriction within the refrigerant movement.

Diagnostic Procedures for PCB Failures

A scientific method is critical to determine the precise reason behind the PCB failure. These procedures emphasize methodical testing and inspection.

Understanding air conditioner PCB board performance is essential, however the associated upkeep usually extends past the board itself. Correct lubrication, like that present in air compressor oil and gas , performs an important function within the longevity of the complete system, influencing the efficiency of the compressor and different elements. Finally, optimizing the system’s lifespan hinges on the correct care and upkeep of the air conditioner PCB board.

- Visible Inspection: Fastidiously examine the PCB for any seen harm, comparable to burnt elements, cracked traces, or free connections. Search for indicators of corrosion or bodily harm, as these can point out the presence of environmental points.

- Energy Provide Testing: Use a multimeter to confirm the presence and voltage ranges of the facility provide to the PCB. This helps isolate any points throughout the energy provide circuit.

- Part Testing: Test the resistance, voltage, and present of particular person elements utilizing a multimeter. Examine these readings to the specs supplied within the service handbook or datasheet for the part.

- Sign Integrity Evaluation: Use an oscilloscope to look at {the electrical} indicators flowing by means of the circuit. This helps determine timing points or anomalies within the management indicators.

Diagnostic Instruments for PCB Evaluation

Utilizing acceptable diagnostic instruments considerably enhances the accuracy and effectivity of PCB board evaluation. This desk supplies an summary of widespread instruments and their purposes.

| Software | Description | Utility |

|---|---|---|

| Multimeter | Measures voltage, present, and resistance. | Figuring out open circuits, quick circuits, and part values. |

| Oscilloscope | Shows electrical waveforms. | Analyzing sign integrity and figuring out timing points. |

| Logic Analyzer | Captures digital indicators. | Inspecting digital circuits and communication protocols. |

| Thermal Imager | Detects temperature variations. | Finding overheating elements and warmth sinks. |

PCB Board Design Issues

Air conditioner PCB boards are complicated digital techniques, demanding meticulous design to make sure optimum efficiency, reliability, and sturdiness. Cautious consideration of thermal administration, part choice, sign integrity, and protecting measures is paramount to the longevity and effectivity of the complete unit. These issues straight influence the cooling capability, power effectivity, and in the end, the consumer expertise.Efficient design ideas are important for minimizing failures and maximizing the lifespan of the air conditioner.

Cautious number of elements, sturdy thermal administration methods, and a give attention to sign integrity are key elements contributing to a dependable and environment friendly PCB. This complete method ends in a high-quality product that meets each practical and efficiency necessities.

Thermal Administration

Thermal administration is essential for air conditioner PCB boards. Extreme warmth can result in part degradation, lowered lifespan, and even catastrophic failures. Implementing efficient warmth dissipation methods is significant for sustaining optimum working temperatures. This includes utilizing acceptable warmth sinks, thermal pads, and cautious part placement to make sure correct warmth switch away from delicate elements. A well-designed thermal administration system ensures constant efficiency and prevents overheating.

Part Choice

Deciding on acceptable elements is a basic facet of air conditioner PCB design. Elements should be chosen based mostly on their electrical specs, thermal traits, and environmental tolerances. Components comparable to voltage scores, present dealing with capability, and working temperature ranges should be thought-about to ensure dependable operation throughout the air conditioner’s anticipated setting. The selection of elements considerably impacts the general efficiency and reliability of the PCB.

Troubleshooting an air conditioner’s PCB board usually includes understanding the intricate connections throughout the system. As an example, should you’re coping with the same difficulty on a large-scale industrial compressor, referencing the detailed elements diagrams within the Ingersoll Rand air compressor elements PDF ingersoll rand air compressor parts pdf may present precious insights into part identification and potential restore procedures.

Finally, appropriately diagnosing and repairing the air conditioner PCB board depends on a radical understanding of the precise unit’s design.

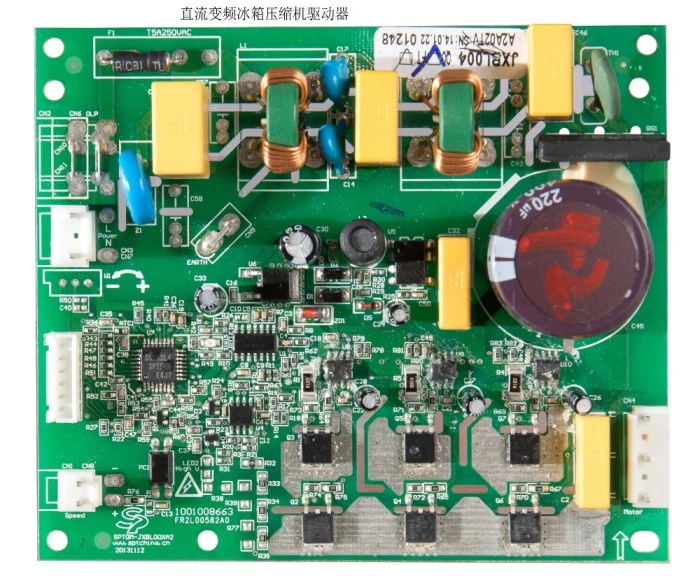

Crucial Elements and Specs, Air conditioner pcb board

A number of essential elements are widespread in air conditioner PCB boards. These embody energy MOSFETs, capacitors, relays, and sensors. Every part performs an important function within the total performance of the system. Particular specs for every part needs to be fastidiously reviewed and chosen to satisfy the actual calls for of the applying. As an example, energy MOSFETs should be able to dealing with the excessive currents related to the compressor.

- Energy MOSFETs: Excessive present dealing with functionality, low on-resistance, and sturdy thermal traits are important for these elements. Their choice straight impacts the effectivity and reliability of the facility circuitry.

- Capacitors: Excessive voltage and capacitance scores are important for filtering and storing power. The selection of capacitor know-how (e.g., electrolytic, ceramic) will depend on the precise software necessities.

- Relays: Dependable switching of excessive currents is important for numerous features, comparable to controlling the compressor. Issues embody switching velocity, contact resistance, and thermal efficiency.

- Sensors: Accuracy and stability of sensors, comparable to temperature and humidity sensors, are essential for correct management of the air con system. Calibration and reliability are necessary features to contemplate.

Sign Integrity and Noise Discount

Sustaining sign integrity and lowering noise are paramount for dependable communication between elements on the PCB. Noise can result in errors and malfunctioning, particularly in management techniques. Cautious routing, shielding, and impedance matching strategies are mandatory to attenuate sign distortion and noise interference. A sturdy design ensures secure and dependable management indicators.

Troubleshooting an air conditioner PCB board might be difficult, requiring a deep dive into electrical circuits. The same dedication to high quality is obvious within the air force veteran hoodie , a bit of attire that speaks to resilience and laborious work, simply as a well-functioning air conditioner PCB board does. Finally, each require a deep understanding of their respective techniques to operate optimally.

Reliability and Sturdiness

Making certain the reliability and sturdiness of the air conditioner PCB board is essential for long-term efficiency. Protecting coatings can defend elements from environmental hazards like moisture and corrosive substances. Strong part placement and safe soldering strategies forestall part detachment or motion, enhancing sturdiness. The PCB’s bodily construction ought to face up to vibrations and shocks throughout operation and transportation.

PCB Materials Comparability

The selection of PCB materials considerably impacts the thermal efficiency and value of the air conditioner PCB board. Completely different supplies exhibit various ranges of thermal conductivity and value. Cautious consideration of those elements is critical for optimum design.

| Materials | Thermal Conductivity | Price |

|---|---|---|

| FR4 | Average | Reasonably priced |

| CEM-1 | Excessive | Increased price |

| PTFE | Very excessive | Very excessive price |

Part Stage Evaluation

Understanding the intricate elements of an air conditioner’s PCB is essential for efficient troubleshooting and upkeep. This evaluation delves into the specifics of widespread elements, their features, potential dangers, and the significance of correct set up. A deep understanding of those elements empowers technicians to diagnose points swiftly and implement optimum restore methods.

Troubleshooting an air conditioner PCB board might be difficult, requiring a deep dive into electrical circuits. The same dedication to high quality is obvious within the air force veteran hoodie , a bit of attire that speaks to resilience and laborious work, simply as a well-functioning air conditioner PCB board does. Finally, each require a deep understanding of their respective techniques to operate optimally.

Frequent Elements and Their Features

Air conditioner PCB boards make the most of a wide range of elements, every enjoying a particular function within the total system. A complete understanding of those elements is important for troubleshooting and preventative upkeep. This part supplies an in depth overview of those elements.

- Resistors: Resistors restrict present movement in particular circuits, making certain elements function inside their designed parameters. They’re important for voltage regulation and present management. Their values, usually starting from 100 ohms to 100k ohms, are chosen to attain the specified impact on the circuit’s present movement.

- Capacitors: Capacitors retailer and launch electrical power, usually utilized in filtering and smoothing voltage fluctuations. Completely different capacitor sorts, together with electrolytic and ceramic, provide numerous traits, impacting the system’s efficiency. Typical capacitance values vary from 0.1µF to 10µF, tailoring the system’s response to numerous frequencies.

- Transistors: Transistors act as switches or amplifiers, controlling the movement of present throughout the circuit. Varied transistor sorts, comparable to 2N2222 and 2N3904, are used based mostly on the required switching or amplification traits. Their choice is important for the system’s effectivity and response time.

- Diodes: Diodes permit present movement in a single route, important for rectifying alternating present to direct present and defending elements from reverse voltage. Completely different diode sorts, like Schottky and general-purpose diodes, are chosen for particular circuit wants.

Evaluating Capacitor Sorts

Completely different capacitor sorts provide various traits, impacting their efficiency in air conditioner PCB circuits. Understanding these distinctions is significant for choosing the proper part for a particular software.

- Electrolytic Capacitors: These capacitors provide excessive capacitance values in a compact measurement, ultimate for filtering and smoothing purposes. Nevertheless, they’ve a polarity and are delicate to reverse voltage, which might result in failure. They’re usually utilized in energy provide circuits.

- Ceramic Capacitors: These capacitors are smaller and cheaper than electrolytic capacitors. They’ve a wider vary of capacitance values, are extra secure throughout totally different temperatures, and are extra immune to voltage surges. Their use is commonly prioritized for purposes demanding stability and compactness.

- Movie Capacitors: These capacitors are famend for his or her excessive stability, low leakage present, and excessive voltage scores. Their exact capacitance values make them appropriate for purposes requiring accuracy and reliability. They’re notably necessary in purposes the place excessive precision and stability are important.

Part Degradation and Failure Dangers

Part degradation and failure are vital dangers in air conditioner PCB boards. Figuring out and mitigating these dangers are essential for system reliability.

- Overheating: Extreme warmth can result in part degradation and failure, particularly for semiconductors. Correct thermal administration and warmth dissipation are essential for prolonging part lifespan.

- Electrochemical Degradation: Sure elements, notably capacitors, can degrade over time attributable to electrochemical reactions. Moisture ingress or poor insulation can speed up this course of. Cautious environmental issues are important.

- Mechanical Stress: Elements might be prone to wreck from vibration, shock, or improper dealing with throughout meeting or operation. Strong packaging and dealing with procedures are essential for making certain part integrity.

Part Placement and Soldering

Applicable part placement and soldering strategies are paramount for making certain the dependable functioning of air conditioner PCB boards.

- Optimum Placement: Part placement ought to contemplate thermal administration, sign integrity, and part performance. Cautious planning and adherence to schematic diagrams are very important.

- Soldering High quality: Correct soldering strategies guarantee robust, dependable connections. Insufficient soldering can result in free connections, chilly joints, or open circuits. Using high-quality solder and correct instruments is essential for high-quality soldering.

Electrical Traits of Frequent Elements

The desk beneath presents {the electrical} traits of widespread elements utilized in air con PCB boards. These traits are essential for circuit design and evaluation.

| Part Kind | Perform | Typical Worth |

|---|---|---|

| Resistor | Limiting present | 100 ohms – 100k ohms |

| Capacitor | Filtering, smoothing | 0.1µF – 10µF |

| Transistor | Switching, amplification | 2N2222, 2N3904 |

Final Recap

In conclusion, mastering air conditioner PCB boards requires a mix of technical experience and sensible data. This information has supplied a framework for understanding the assorted sides of those essential elements, from troubleshooting to design optimization. By greedy the nuances of diagnostics, design ideas, and part evaluation, you will be geared up to sort out any problem associated to air conditioner PCB boards.

FAQ Useful resource

What are the most typical causes of an air conditioner not turning on?

Frequent causes embody a defective energy provide, tripped circuit breakers, or points with the management board itself. A radical inspection of those areas is significant for efficient troubleshooting.

How can I inform if the capacitor on the air conditioner PCB is unhealthy?

A defective capacitor usually manifests as erratic efficiency, comparable to biking on and off or inconsistent cooling. A multimeter can be utilized to verify its capacitance and voltage scores.

What are the various kinds of PCB supplies utilized in air conditioners and what are their execs and cons?

FR4 is a typical, reasonably priced possibility, whereas CEM-1 affords increased thermal conductivity, and PTFE excels in high-temperature environments. Selecting the best materials will depend on the precise working circumstances and value constraints.

What are some superior diagnostic instruments used for air conditioner PCB board evaluation?

Past multimeters, oscilloscopes and logic analyzers present insights into electrical waveforms and digital indicators, serving to to pinpoint points associated to sign integrity and communication protocols. Thermal imaging is helpful for figuring out overheating elements.