Air compressor magnetic starter is a vital part in industrial settings. Understanding its intricacies, from elements to troubleshooting, is crucial for optimum efficiency and longevity. This information delves deep into the internal workings of those important starters, providing sensible insights and actionable steps to make sure seamless operation.

This in-depth exploration covers every part from the detailed specs of assorted elements like contactors and overload relays to the operational ideas of the starter itself. We’ll additionally look at completely different management strategies, troubleshooting methods, and important upkeep procedures. Put together to raise your understanding of air compressor magnetic starters.

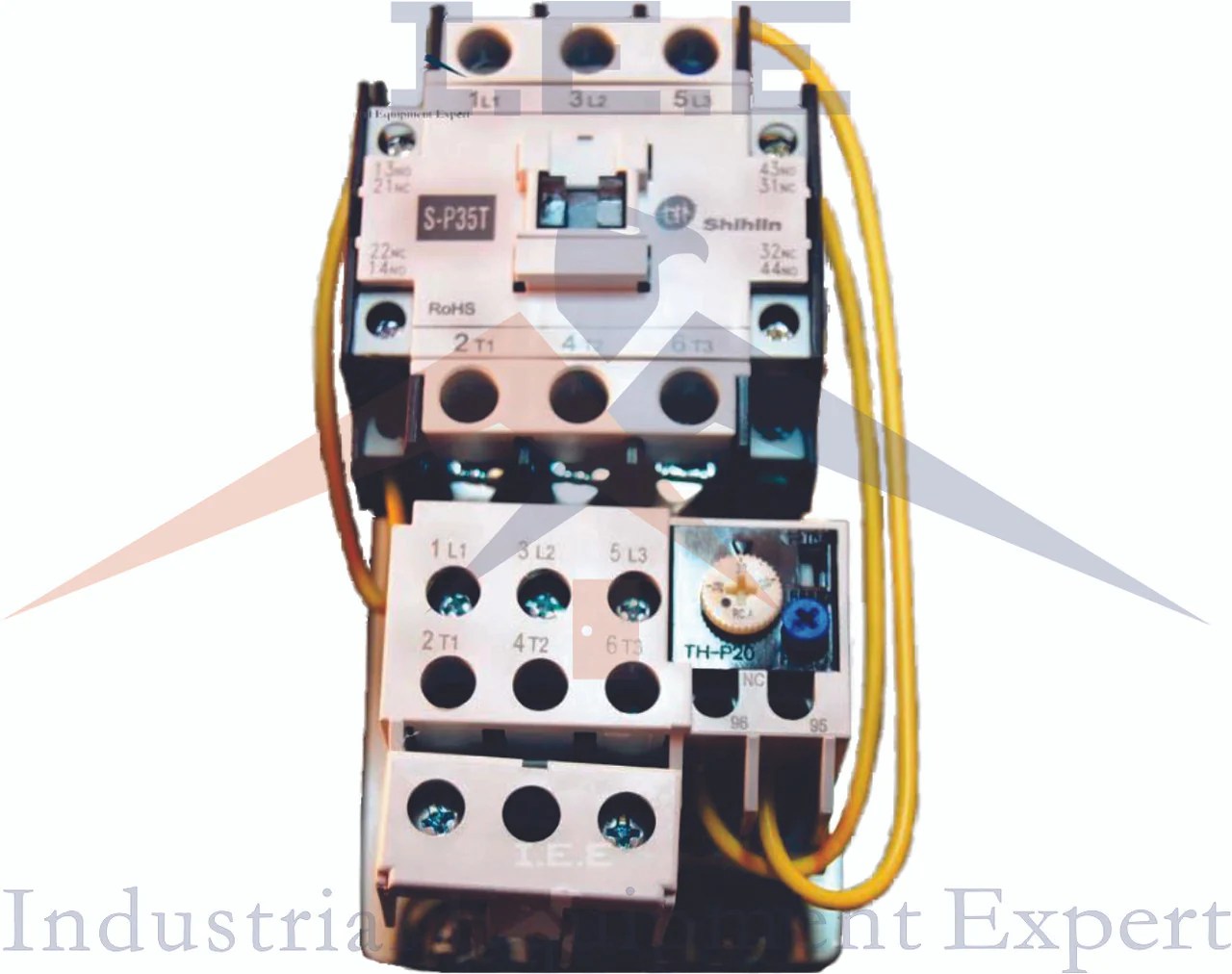

Air Compressor Magnetic Starter Parts

Understanding the intricate elements of an air compressor magnetic starter is essential for its environment friendly and dependable operation. Correct upkeep and troubleshooting depend on a transparent comprehension of how every half contributes to the general performance. A stable grasp of those components permits for proactive problem-solving and optimized efficiency.The air compressor magnetic starter acts because the management system for initiating and stopping the compressor motor.

This electromechanical gadget is a essential part in guaranteeing secure and managed operation, particularly in industrial settings the place large-scale air compression is crucial. Its dependable operation immediately impacts productiveness and effectivity.

Magnetic Starter Contactor

The contactor is the guts of the magnetic starter. It is a change that closes and opens the circuit to the motor utilizing an electromagnet. When the starter receives a sign, the electromagnet energizes, pulling the contacts collectively, finishing the circuit and permitting present to circulate to the motor. This enables the compressor to begin. When the sign is eliminated, the electromagnet de-energizes, the contacts separate, and the motor is shut off.

This significant switching mechanism is prime to the starter’s operate.

Coil

The coil is the electromagnet inside the contactor. It is designed to obtain electrical energy, producing a magnetic subject that prompts the contactor. The coil’s specs, together with voltage and amperage rankings, are essential to the starter’s efficiency. A appropriately sized coil ensures dependable operation and prevents injury from extreme present circulate. The coil’s insulation high quality can be paramount for security and longevity.

Overload Relay

The overload relay is a security gadget that protects the motor from overheating. It displays the present flowing by means of the motor. If the present exceeds a predetermined secure restrict, the relay journeys, opening the circuit and stopping injury to the motor windings. This significant part prevents expensive repairs and downtime. The relay’s setting should be fastidiously adjusted to match the motor’s specs for optimum safety.

Auxiliary Contacts

Auxiliary contacts are supplementary contacts which are included into the contactor. They’re used to regulate different circuits, reminiscent of lights, alarms, or different management mechanisms. This function is especially helpful in industrial settings, the place further management alerts are sometimes needed. They supply a handy option to combine the magnetic starter into extra advanced management programs.

Different Vital Parts

Different elements, reminiscent of terminal blocks, mounting brackets, and enclosures, are important for the starter’s performance and security. These elements contribute to the starter’s structural integrity and facilitate correct electrical connections. Cautious consideration of those supporting components is essential for the long-term reliability and secure operation of the magnetic starter.

Magnetic Starter Sorts

Several types of magnetic starters cater to various air compressor wants. These variations are based mostly on capability, voltage, and management mechanisms. Choosing the suitable sort is essential for optimum efficiency. Some sorts are particularly designed for high-horsepower purposes, whereas others are appropriate for smaller compressors. Particular management options may also be essential, reminiscent of completely different overload safety or a number of begin/cease choices.

Magnetic Starter Specs

| Element | Specification | Attribute | Diagram |

|---|---|---|---|

| Contactor | Voltage, Amperage, Contact Ranking | Switching capability, contact materials | (Diagram of a contactor) |

| Coil | Voltage, Amperage, Wattage | Working traits, insulation | (Diagram of a coil) |

| Overload Relay | Journey Present Setting, Time Delay | Safety degree, responsiveness | (Diagram of an overload relay) |

Operation and Management Mechanisms: Air Compressor Magnetic Starter

Air compressor magnetic starters are essential elements in guaranteeing the graceful and secure operation of compressed air programs. Understanding their operational ideas and management mechanisms is crucial for optimizing efficiency, stopping injury, and sustaining a secure working setting. Correct management ensures constant strain, dependable output, and prolonged lifespan of the whole system.The operational sequence of a magnetic starter begins with the energization of the coil.

This energizes the electromagnet, which in flip pulls the contactor’s movable elements collectively, closing {the electrical} circuit. This enables present to circulate to the air compressor motor, initiating its operation. Conversely, de-energization of the coil releases the electromagnet, opening the circuit, and stopping the motor. This exact sequence is essential for dependable and environment friendly operation.

Operational Ideas

The elemental precept of a magnetic starter lies in its skill to remotely and safely management the operation of a high-power motor. The method includes a low-voltage management circuit that prompts a high-voltage energy circuit. This essential separation of management and energy circuits is a elementary security function. The magnetic starter acts as an middleman, guaranteeing the motor begins and stops reliably.

That is notably important in purposes requiring distant or automated management. The sequence includes a management circuit activating a contactor, which then completes the ability circuit to the compressor motor. The method is reversible, permitting for managed start-up and shutdown.

Management Strategies

Numerous management strategies present flexibility and security in working and controlling air compressor magnetic starters. Handbook begin/cease buttons present localized management, whereas distant management panels supply a wider vary of management choices. Security interlocks are essential to stop unintended operation, guaranteeing the system is secure for upkeep or in emergency conditions. These interlocks present essential safeguards.

Wiring and Connections

Right wiring and connections are paramount for the secure and dependable operation of the air compressor magnetic starter. Improper connections can result in electrical hazards, motor injury, and system failure. A meticulous method is critical to make sure a secure and dependable system. This includes understanding {the electrical} specs of the motor and starter. The diagrams beneath illustrate frequent wiring setups for magnetic starters.

| Diagram | Description | Connections |

|---|---|---|

| Diagram 1 | Fundamental wiring for a single-phase air compressor. | Section 1, Section 2, Impartial, Begin Button, Cease Button, Overload Relay, Compressor Motor. |

| Diagram 2 | Wiring for a three-phase air compressor with a distant management panel. | Section 1, Section 2, Section 3, Impartial, Distant Begin/Cease Switches, Overload Relay, Compressor Motor. |

Overload Safety

Overload safety is a crucial security function in magnetic starters, safeguarding the motor from injury as a result of extreme present. Several types of overload safety mechanisms are employed to stop motor burnout and system failure. These units sense present circulate and, if needed, interrupt the ability provide to the motor. This prevents motor injury.Fuses and circuit breakers present a easy and cost-effective technique of overload safety.

Thermal overload relays, nonetheless, are extra subtle and might supply extra exact management. They monitor the motor’s temperature and might shut down the motor if the temperature exceeds secure limits. This prevents thermal injury. Thermal overload relays are broadly used for his or her skill to guard the motor from extreme warmth. They’re a key part of a complete safety system.

Troubleshooting and Upkeep

Air compressor magnetic starters are essential for dependable operation. Correct troubleshooting and upkeep are important to make sure optimum efficiency, stop expensive downtime, and prolong the lifespan of the gear. Addressing potential points proactively is essential to minimizing sudden disruptions and maximizing operational effectivity.Efficient troubleshooting includes figuring out the foundation reason behind malfunctions and implementing the suitable corrective measures. A well-defined upkeep schedule ensures that preventative actions are taken, thereby lowering the probability of main breakdowns.

This method minimizes downtime and maximizes the general return on funding.

Frequent Points and Malfunctions

Air compressor magnetic starters can expertise varied malfunctions, starting from minor operational hiccups to finish failures. These points might be attributed to a number of elements, together with part put on, environmental circumstances, and improper set up or operation. Understanding these potential issues is step one in efficient troubleshooting. Some frequent malfunctions embrace:

- Overheating: Extreme warmth buildup within the starter can point out issues with the windings, contacts, or cooling system. This may result in injury and untimely failure.

- Tripping: Frequent or sudden tripping of the starter might recommend an issue with the overload safety or a fault within the compressor itself. This is also attributable to voltage fluctuations.

- No Begin Situation: The starter might fail to have interaction the motor, indicating points with the management circuitry, the starter itself, or the motor.

- Erratic Operation: Irregular motor operation, together with pace fluctuations or vibrations, may level to an issue with the starter, the motor, or the load.

Troubleshooting Steps

A scientific method to troubleshooting is essential. A step-by-step course of helps to pinpoint the supply of the difficulty.

- Preliminary Evaluation: Fastidiously look at the starter for seen indicators of injury, reminiscent of burnt elements or unfastened connections. Examine the air compressor’s working parameters and guarantee they’re inside the really helpful vary. Confirm the ability provide to the starter.

- Confirm the Circuit: Examine the wiring connections and guarantee correct grounding. Take a look at the continuity of the wiring to detect any open circuits. Use a multimeter to verify for proper voltage and amperage.

- Examine Parts: Fastidiously examine the starter elements, paying explicit consideration to the windings, contacts, and relays. Examine for indicators of overheating, corrosion, or bodily injury. Search for indicators of arcing on the contacts.

- Examine the Overload Relay: Confirm the overload relay’s performance. Guarantee it’s correctly calibrated and attentive to overcurrent circumstances. If a relay is suspect, change it.

- Examine the Management Circuit: If the difficulty persists, examine the management circuitry for any points. This may increasingly contain checking the wiring diagrams and verifying the performance of all management elements.

Upkeep Schedule

A well-defined upkeep schedule is essential for maximizing the lifetime of an air compressor magnetic starter.

- Common Visible Inspection: Conduct a visible inspection of the starter for any indicators of injury or put on not less than month-to-month. Word any uncommon noises or temperatures.

- Periodic Electrical Testing: Carry out periodic electrical exams to verify for continuity, insulation resistance, and voltage ranges not less than quarterly. This may be finished with a multimeter.

- Lubrication and Cleansing: Clear the starter and lubricate transferring elements as wanted. It will stop untimely put on and tear.

- Element Alternative: Exchange worn or broken elements, reminiscent of relays or contacts, as needed to take care of optimum efficiency. Following producer suggestions is important.

Changing a Defective Element

Security is paramount throughout part substitute.

- Security Precautions: Disconnect the ability provide to the magnetic starter earlier than performing any upkeep. Put on applicable security gear, reminiscent of gloves and eye safety.

- Element Identification: Determine the precise defective part and procure the right substitute half from the producer.

- Elimination Process: Comply with the producer’s directions to securely take away the defective part.

- Set up Process: Fastidiously set up the brand new part following the producer’s directions. Guarantee correct connections and alignment.

- Verification: Reconnect the ability provide and confirm that the starter operates appropriately.

Error Codes and Options, Air compressor magnetic starter

Decoding error codes can rapidly diagnose the difficulty.

| Error Code | Description | Resolution |

|---|---|---|

| E01 | Overload | Examine the compressor load, scale back load, or verify the starter’s overload settings. |

| E02 | Low Voltage | Examine the ability provide, guarantee correct voltage ranges, or verify the wiring connections. |

| E03 | Excessive Voltage | Examine the ability provide, guarantee correct voltage ranges, or verify the wiring connections. |

| E04 | Section Failure | Examine the ability provide, guarantee correct voltage ranges, or verify the wiring connections. |

| E05 | Inner Fault | Contact a professional technician to evaluate the starter. |

Ending Remarks

In conclusion, mastering air compressor magnetic starters is a key step in maximizing effectivity and minimizing downtime in any industrial setting. By greedy the elements, operation, and troubleshooting procedures detailed on this information, you may be outfitted to take care of and optimize the efficiency of your air compressor system. This information empowers you to confidently tackle potential points and guarantee peak efficiency out of your magnetic starter.

FAQ Defined

What are the frequent causes of a magnetic starter malfunction?

Frequent causes of magnetic starter malfunctions embrace defective wiring, broken elements just like the contactor or overload relay, and points with the management circuit. Overheating, as a result of extreme load or inadequate cooling, is one other frequent wrongdoer. Understanding these potential issues is step one in efficient troubleshooting.

How typically ought to an air compressor magnetic starter be inspected and maintained?

Common upkeep is essential. A preventive upkeep schedule ought to embrace visible inspections for indicators of damage, reminiscent of corrosion or unfastened connections. Routine checks of the overload relays and contactors are important to make sure dependable efficiency. Particular schedules rely upon the working setting and utilization frequency, however common inspection is all the time key.

What are the protection precautions when working with air compressor magnetic starters?

Security ought to all the time be paramount. Guarantee the ability provide to the starter is disconnected earlier than any upkeep or troubleshooting is carried out. Correct private protecting gear (PPE) like security glasses and gloves ought to be worn to mitigate potential hazards. All the time seek the advice of the producer’s tips for particular security procedures associated to your particular mannequin.

What are the various kinds of management mechanisms used for air compressor magnetic starters?

Numerous management strategies exist, starting from easy handbook begin/cease buttons to stylish distant management panels and security interlocks. The particular management mechanism chosen relies on the specified degree of automation and security necessities. Understanding the choices out there permits for optimum management setup.