Air brake hose 3 8 – Air brake hose 3/8 is essential for the graceful and secure operation of many autos. Understanding its specs, set up, upkeep, and troubleshooting is important for stopping pricey breakdowns and making certain optimum efficiency. This information dives deep into every part you’ll want to find out about this important part, from materials composition and differing kinds to set up procedures and troubleshooting strategies.

This detailed breakdown covers every part from the elemental traits of a 3/8″ air brake hose to the intricate steps concerned in its upkeep and restore. We’ll discover the assorted varieties out there, evaluating their strengths and weaknesses, and delve into the essential facets of set up and security precautions. You may discover ways to determine and tackle potential points, finally gaining the information to maintain your air brake system operating effectively.

Air Brake Hose Specs

Understanding air brake hose specs is essential for sustaining secure and dependable operation of autos. Correct choice and upkeep of those hoses are important to forestall accidents and guarantee compliance with trade laws. This data is important for technicians, fleet managers, and anybody concerned within the inspection or upkeep of autos using air brake programs.Air brake hoses are important elements of economic automobile programs, transmitting compressed air to regulate braking mechanisms.

Their sturdiness, materials composition, and development immediately affect security and longevity. Choosing the proper kind of air brake hose is important to forestall pricey failures and guarantee compliance with security requirements.

Understanding the intricacies of air brake hose 3/8 inch is essential for any mechanic. This data turns into much more precious when contemplating the logistics of a significant occasion just like the Leon Scorching Air Balloon Competition, which frequently requires specialised transportation and gear. Correctly sustaining and deciding on the precise air brake hose 3/8 is vital for making certain security and easy operations, particularly throughout high-traffic intervals just like the Leon Scorching Air Balloon Competition.

This data interprets immediately into environment friendly and secure efficiency for any automobile, together with these concerned within the logistics of this occasion.

Materials Composition and Development

A 3/8″ air brake hose sometimes incorporates a rubber internal tube encased in a protecting outer layer. This outer layer can fluctuate considerably, impacting the hose’s stress ranking, sturdiness, and total value. The internal tube is essential for air transmission, whereas the outer layer protects in opposition to exterior injury and stress fluctuations. Frequent supplies for the outer layer embody metal wire braid, strengthened layers of rubber, or a mix of each.

These totally different supplies supply various ranges of power and resilience.

Forms of 3/8″ Air Brake Hoses

A number of varieties of 3/8″ air brake hoses can be found, every designed for particular purposes and environments. This selection permits for choice primarily based on elements like anticipated stress, working temperature, and potential publicity to corrosive substances.

Air brake hose 3/8 inch connections are essential for environment friendly pneumatic programs. Correctly sustaining these hoses, alongside elements just like the 32/36 Weber air filter , ensures optimum efficiency. In the end, dependable air brake hose 3/8 inch connections are important for security and operational effectivity.

- Braided hoses supply distinctive sturdiness and excessive stress scores. Their development makes use of metal wire braid, offering superior resistance to abrasion and kinking. Braided hoses are ceaselessly chosen for demanding purposes the place excessive stress and excessive situations are anticipated. Examples embody heavy-duty vehicles working in harsh climates or autos requiring excessive braking energy.

- Strengthened hoses mix the power of metal wire reinforcement with a rubber outer layer. This mix offers a stability between sturdiness and value. These hoses are well-suited for purposes requiring good sturdiness and a average stress ranking. They’re a preferred selection for general-purpose use in business autos, the place cost-effectiveness is a big issue.

- Normal rubber hoses are sometimes essentially the most reasonably priced possibility. They make the most of a regular rubber outer layer for cover. Whereas cost-effective, these hoses usually have decrease stress scores and lowered sturdiness in comparison with braided or strengthened varieties. They’re greatest fitted to purposes with average stress and fewer demanding working situations. An instance is likely to be a light-duty supply automobile the place the next stress ranking isn’t vital.

Air brake hose 3/8 inch connections are essential for environment friendly pneumatic programs. Discovering the precise adapters, like a 3/8 to 1/4 adapter air hose , is important for seamless transitions between totally different sizes, finally making certain correct operate of your complete system. Correctly sized and related air brake hose 3/8 inch elements stay vital for optimum efficiency.

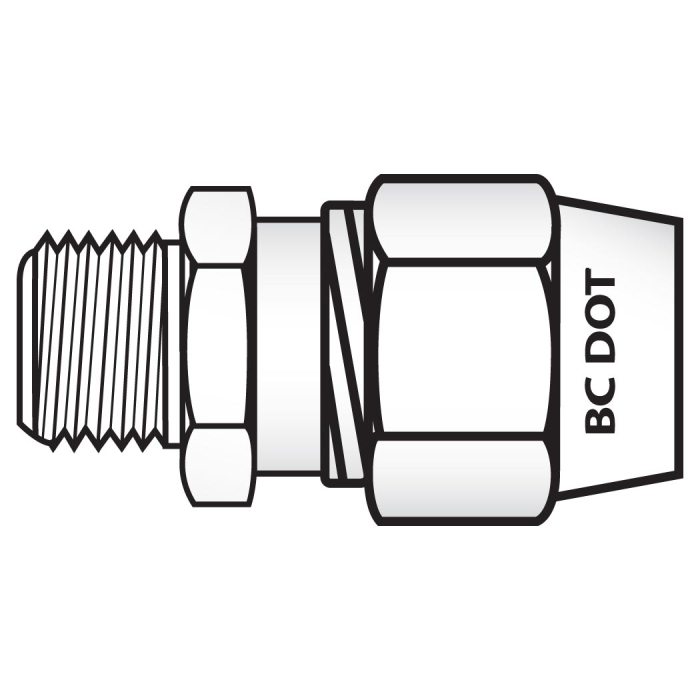

Requirements and Rules

The manufacturing and use of three/8″ air brake hoses are ruled by quite a few requirements and laws to make sure security and efficiency. These laws cowl materials specs, development strategies, stress scores, and testing procedures. Adherence to those requirements is vital to forestall failures that would result in accidents. Examples of governing our bodies embody DOT (Division of Transportation) laws and SAE (Society of Automotive Engineers) requirements.

Comparability of three/8″ Air Brake Hose Sorts

The next desk compares the important thing traits of various 3/8″ air brake hose varieties:

| Hose Kind | Materials | Development | Benefits | Disadvantages |

|---|---|---|---|---|

| Braided | Metal Wire | Braided | Sturdy, Excessive Strain Score, Proof against Kinking | Extra Costly, Much less Versatile |

| Strengthened | Metal Wire | Strengthened | Good Sturdiness, Average Value | Much less Versatile than Braided |

| Normal | Rubber | Normal | Inexpensive | Much less Sturdy, Decrease Strain Score |

Set up and Upkeep

Correct set up and meticulous upkeep of three/8″ air brake hoses are essential for security and optimum efficiency. Neglecting these facets can result in catastrophic failures, probably inflicting accidents and important monetary losses. Understanding the intricacies of set up and upkeep procedures empowers customers to increase the lifespan of those vital elements and decrease downtime.Set up procedures for 3/8″ air brake hoses require a meticulous strategy.

Incorrect set up can compromise the integrity of the system, resulting in potential leaks, lowered braking effectivity, and security hazards. An intensive understanding of the process is paramount.

Understanding the intricacies of air brake hose 3/8 inch is essential for any mechanic. This data turns into much more precious when contemplating the logistics of a significant occasion just like the Leon Scorching Air Balloon Competition, which frequently requires specialised transportation and gear. Correctly sustaining and deciding on the precise air brake hose 3/8 is vital for making certain security and easy operations, particularly throughout high-traffic intervals just like the Leon Scorching Air Balloon Competition.

This data interprets immediately into environment friendly and secure efficiency for any automobile, together with these concerned within the logistics of this occasion.

Correct Set up Process

The set up course of begins with meticulous preparation. Guarantee the realm is clear and freed from particles. Examine the hose for any pre-existing injury, corresponding to kinks, cuts, or cracks. Utilizing the suitable instruments is vital for a secure and efficient set up. Incorrect instruments can injury the hose or result in improper connections.

Correctly lubricated fittings forestall leaks and facilitate easy connections.

Obligatory Instruments and Gear

A complete toolkit is important for a profitable set up. This consists of applicable wrenches, pliers, and a lubricant. The precise instruments make sure the integrity of the connection and stop injury to the hose or the part it’s related to. A leak detector is a precious software to shortly determine any potential leaks after set up.

Inspection for Put on and Tear

Common inspections are important for sustaining the integrity of the three/8″ air brake hose. Visible inspections ought to be carried out at common intervals to determine any indicators of damage and tear, corresponding to cracks, kinks, or corrosion. The presence of any of those points indicators the necessity for speedy substitute.

Step-by-Step Inspection Information, Air brake hose 3 8

- Visually examine your complete hose for any indicators of harm, corresponding to cracks, cuts, or bulges.

- Verify for any indicators of kinking or sharp bends within the hose.

- Study the fittings for any indicators of corrosion, rust, or injury.

- Really feel the hose for any uncommon hardness or stiffness, which could point out inner injury.

- Pay attention for any hissing sounds, which may point out a leak.

- Guarantee all connections are safe and tight.

- Take a look at the hose for leaks by making use of slight stress to the system.

Frequent Causes of Failure and Preventive Measures

| Trigger | Prevention |

|---|---|

| Kinking | Keep away from sharp bends and make sure the hose is routed correctly. |

| Abrasion | Shield the hose from contact with sharp edges or tough surfaces. |

| Corrosion | Common cleansing and inspection to forestall rust and deterioration. |

| Over-pressure | Keep the proper air stress specified by the producer’s tips. |

Troubleshooting and Restore

Air brake hoses are vital elements in sustaining secure automobile operation. Correct analysis and restore are important to forestall pricey failures and potential accidents. Understanding frequent points and their corresponding signs is vital to environment friendly troubleshooting. This part delves into the sensible facets of figuring out and rectifying issues with 3/8″ air brake hoses.Diagnosing issues with 3/8″ air brake hoses requires a scientific strategy.

Troubleshooting air brake hose 3/8″ points typically entails a scientific strategy, together with checking for leaks and correct connections. Generally, seemingly unrelated issues like an outdoor air-con unit not operating can impact related systems , highlighting the interconnectedness of assorted mechanical elements. In the end, correct analysis and correct substitute of air brake hose 3/8″ components are essential for optimum automobile operate.

An intensive visible inspection is commonly step one. Search for apparent indicators of harm, corresponding to cracks, bulges, or tears. These visible cues can point out underlying points.

Frequent Issues and Signs

Figuring out the supply of an issue in a 3/8″ air brake hose is commonly simple, offered you perceive the standard signs. Air leaks are a main concern. These leaks manifest as a lack of braking stress, probably resulting in lowered braking energy or whole brake failure. Different indicators embody uncommon noises, like hissing or whistling, coming from the hose.

A sudden drop in air stress inside the system additionally warrants speedy consideration. Understanding the particular signs related to every potential downside is vital for efficient analysis.

Strategies for Diagnosing Leaks or Malfunctions

Correct analysis begins with a radical visible inspection. This consists of checking for bodily injury like cracks, cuts, or pinholes. A leak detector is a precious software, permitting for the identification of hidden leaks. Making use of soapy water to suspect areas helps pinpoint the precise location of the leak. This technique is efficient as a result of the cleaning soap bubbles readily reveal the air escaping via minute breaches within the hose’s integrity.

Pay attention for uncommon noises, corresponding to hissing or whistling, which may additionally point out leaks.

Restore Procedures

As soon as a leak or malfunction is recognized, the suitable restore process have to be adopted. Security is paramount. At all times disconnect the air provide earlier than engaged on the air brake system. The restore technique typically depends upon the severity of the injury. Minor cracks or tears can generally be repaired utilizing a specialised restore package.

For extra intensive injury, substitute is the beneficial resolution. Detailed directions on the process for changing a broken 3/8″ air brake hose are offered under.

Changing a Broken 3/8″ Air Brake Hose

A scientific strategy to changing a broken 3/8″ air brake hose ensures security and effectivity. Following the steps under will information you thru the method.

Step 1: Find the broken hose. Step 2: Shut off the air provide.Step 3: Disconnect the hose from the elements.Step 4: Set up the brand new hose.Step 5: Reconnect the hose and switch the air provide again on.

Correctly changing a 3/8″ air brake hose is essential for sustaining the integrity of your complete air brake system. This meticulous process ensures optimum efficiency and prevents additional issues.

Ultimate Conclusion

In conclusion, mastering air brake hose 3/8 information empowers you to take care of optimum automobile efficiency and security. By understanding the specs, set up procedures, and troubleshooting strategies Artikeld on this information, you will be well-equipped to handle any challenges that come up. Keep in mind that security is paramount when working with air brake programs. Thorough inspection and adherence to correct procedures are essential for stopping accidents and making certain the longevity of your gear.

Detailed FAQs: Air Brake Hose 3 8

What are the frequent causes of air brake hose 3/8 failure?

Frequent causes embody kinking, abrasion, corrosion, and over-pressure. Preventive measures embody avoiding sharp bends, defending the hose from sharp edges, performing common cleansing and inspections, and sustaining the proper air stress.

What are the several types of air brake hose 3/8 out there?

Frequent varieties embody braided, strengthened, and normal. Braided hoses are sturdy and high-pressure rated however dearer. Strengthened hoses supply good sturdiness at a average value. Normal hoses are reasonably priced however much less sturdy and have a decrease stress ranking.

What instruments are wanted for putting in an air brake hose 3/8?

The particular instruments required will rely upon the automobile and the particular set up. Nevertheless, frequent instruments embody applicable wrenches, pliers, and probably specialised hose clamps. At all times consult with your automobile’s upkeep handbook for exact suggestions.

How typically ought to I examine an air brake hose 3/8?

Common inspection schedules fluctuate relying on the working situations and utilization frequency. Seek the advice of your automobile’s upkeep handbook for particular suggestions and tips. Nevertheless, a normal rule of thumb is to examine the hose routinely for any indicators of harm or put on.