Air bag mounting plate design is essential for automobile security. Choosing the proper materials, form, and dimension instantly impacts the effectiveness and reliability of your complete airbag system. Understanding the manufacturing processes and high quality management measures ensures security requirements are met. This in-depth look will study the essential parts of air bag mounting plate design, from materials choice to security laws.

This evaluation delves into the multifaceted concerns surrounding air bag mounting plates. From evaluating varied designs to scrutinizing manufacturing processes and security requirements, we’ll unpack the intricate particulars behind these essential parts. Understanding the specifics will empower readers to make knowledgeable choices, in the end contributing to enhanced automobile security.

Air Bag Mounting Plate Design Concerns

Air bag mounting plates are essential parts in automobile security methods. Their design considerably impacts the effectiveness and reliability of your complete airbag deployment system. Correctly designed plates make sure the airbag inflates appropriately and safely, minimizing harm dangers within the occasion of a crash. This evaluation explores varied design concerns for air bag mounting plates, analyzing supplies, shapes, and sizes, and evaluating their suitability for various automobiles and purposes.Designing an efficient air bag mounting plate includes a posh interaction of things.

Components such because the anticipated load, the precise automobile sort, and the specified efficiency traits all affect the ultimate design. Cautious consideration of those parts is important to creating a sturdy and reliable system.

Materials Choice for Air Bag Mounting Plates

The selection of fabric considerably impacts the plate’s energy, weight, and price. Excessive-strength supplies, resembling aluminum alloys and metal, present wonderful load-bearing capability. Nevertheless, they’re usually dearer than various supplies like plastics strengthened with fiberglass or carbon fiber. The choice course of additionally wants to contemplate corrosion resistance, particularly for purposes in harsh environments.

Form and Measurement Concerns

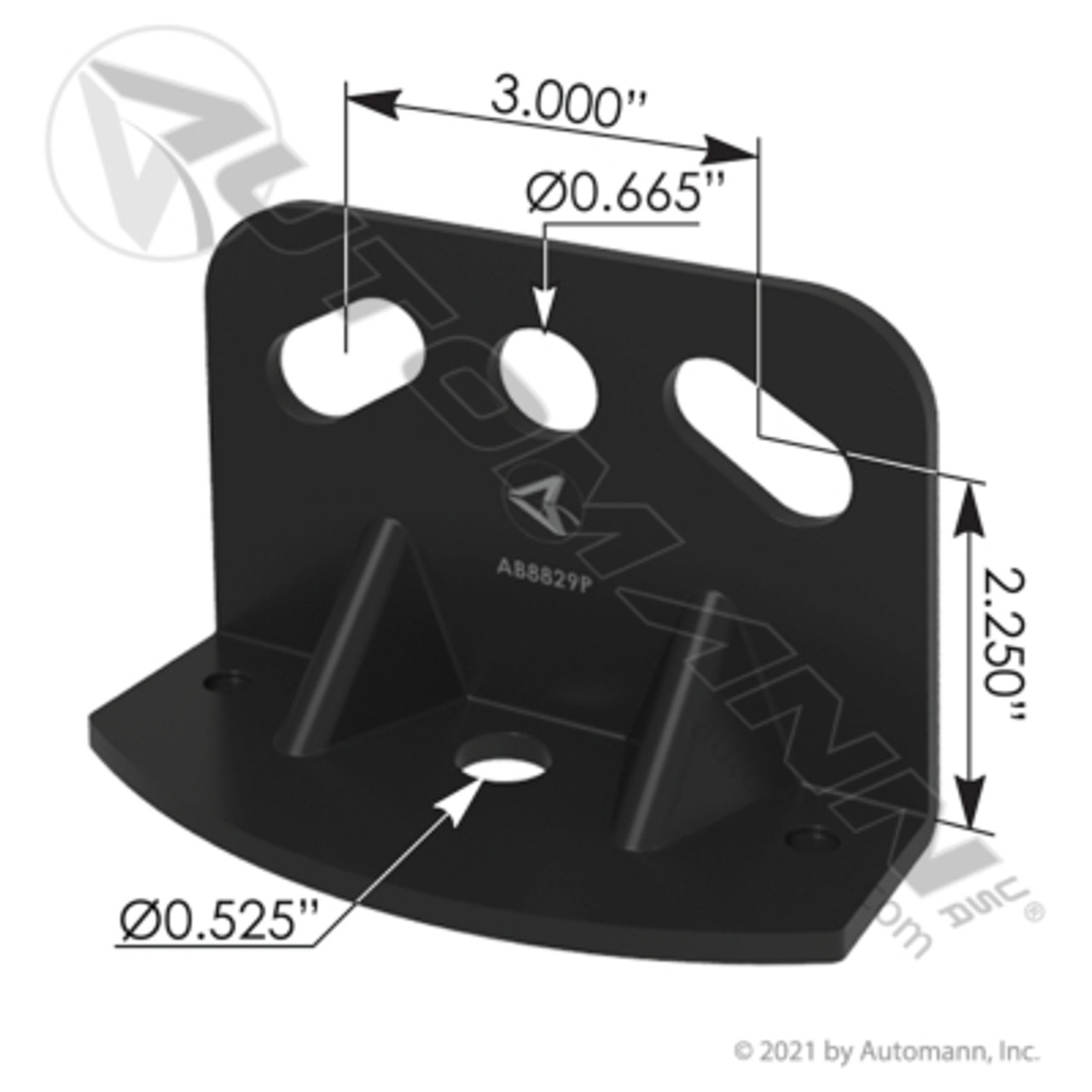

The form and dimension of the mounting plate instantly affect its means to assist the airbag and distribute forces throughout deployment. A well-designed form ensures even drive distribution, stopping deformation or failure of the plate. Particular automobile geometries and airbag traits dictate the optimum dimensions and contours. Completely different automobile sorts, resembling passenger vehicles, vans, or SUVs, require completely different plate designs resulting from variations in airbag sizes and deployment mechanisms.

Load Capability and Sturdiness

Guaranteeing sufficient load capability is paramount for dependable airbag deployment. Over-engineering the plate to deal with excessive hundreds is essential, however unnecessarily heavy plates can influence automobile efficiency. This stability is essential within the design course of. The plate should face up to the substantial forces generated throughout an airbag deployment with out compromising its structural integrity.

Price and Manufacturing Concerns

Price is an important issue within the design course of. The fabric, manufacturing methods, and complexity of the design all affect the ultimate value. The associated fee-effectiveness of a specific design is in comparison with its efficiency and sturdiness traits. Optimizing manufacturing processes can scale back prices whereas sustaining the specified efficiency requirements.

Comparative Evaluation of Mounting Plate Designs

Completely different designs provide varied trade-offs by way of energy, weight, and price. As an illustration, a easy, rectangular design could be cost-effective however might not present the identical degree of load capability as a extra complicated, contoured design. Consideration of the goal automobile sort and deployment forces is important to creating an knowledgeable alternative.

Examples of Profitable Air Bag Mounting Plate Designs

A number of profitable air bag mounting plate designs have demonstrated superior efficiency in crash exams. These designs usually incorporate superior materials science, optimized shapes, and sturdy manufacturing methods. These profitable designs usually characteristic strategically positioned reinforcements to maximise load capability whereas minimizing weight.

Desk of Air Bag Mounting Plate Sorts

| Materials | Dimensions (Size x Width x Peak) | Load Capability (kN) | Price (USD) |

|---|---|---|---|

| Aluminum Alloy 6061-T6 | 100 mm x 150 mm x 20 mm | 15 | 50 |

| Excessive-Energy Metal | 120 mm x 180 mm x 25 mm | 20 | 65 |

| Fiberglass-Bolstered Polymer | 110 mm x 160 mm x 22 mm | 12 | 40 |

Manufacturing Processes and High quality Management

Producing high-quality air bag mounting plates calls for meticulous consideration to element all through the manufacturing course of. These plates are essential parts in guaranteeing the protection and effectiveness of your complete airbag system. From preliminary materials choice to last high quality checks, every step performs a vital function in attaining the specified efficiency and reliability. The manufacturing processes and stringent high quality management measures employed instantly influence the protection of car occupants.Precision and accuracy are paramount within the manufacturing of air bag mounting plates.

Variations in materials thickness, alignment, or part tolerances can compromise the structural integrity of the plate and in the end influence the effectiveness of the airbag deployment. Strict adherence to established manufacturing protocols and complete high quality management measures is important to mitigating these dangers.

Frequent Manufacturing Processes

The manufacturing processes employed for air bag mounting plates usually contain a mixture of methods to realize the required energy, sturdiness, and precision. These processes are chosen primarily based on components resembling materials sort, desired plate geometry, and manufacturing quantity. Frequent strategies embrace stamping, machining, and welding. Correct choice and implementation of those processes are very important to making sure the structural integrity of the plates.

- Stamping: This course of includes utilizing a die to form steel sheets into the specified type. Excessive-precision stamping dies are essential for attaining correct plate dimensions and tolerances. The collection of appropriate metal alloys can be essential for guaranteeing the required energy and sturdiness.

- Machining: This technique is commonly employed for complicated geometries or to refine the scale of stamped plates. Lathes, milling machines, and different precision machining instruments are used to create the required options on the plate, together with cutouts for wiring or mounting factors.

- Welding: In instances the place a number of parts should be joined, welding methods resembling spot welding or laser welding are used to create a robust and dependable connection. The kind of weld and the welding parameters are fastidiously managed to forestall defects that might compromise the plate’s integrity.

High quality Management Measures

Thorough high quality management procedures are important to make sure the protection and reliability of air bag mounting plates. These procedures embody a spread of checks at varied phases of the manufacturing course of. Rigorous testing and inspection procedures are very important to establish and eradicate any potential defects.

- Dimensional Inspection: Exact measurements of plate dimensions, together with thickness, size, and width, are essential to make sure adherence to design specs. Specialised measuring devices, resembling calipers and micrometers, are used for these inspections.

- Visible Inspection: Visible examination of the plates for defects like cracks, burrs, or warping is a essential step within the high quality management course of. Skilled inspectors meticulously scrutinize every plate for any deviations from the established requirements.

- Materials Testing: Testing the fabric properties, resembling tensile energy and yield energy, ensures the chosen materials meets the required efficiency standards. This course of includes subjecting samples of the fabric to managed stress situations to judge its resistance to deformation.

Significance of Precision in Manufacturing

Precision in manufacturing is essential for guaranteeing the protection and reliability of the air bag system. Even minor deviations from the desired tolerances can considerably have an effect on the efficiency of the airbag deployment mechanism. These small inaccuracies may compromise the structural integrity of the plate, which in flip may influence the airbag’s means to deploy appropriately and safely. The flexibility to keep up exact tolerances all through the manufacturing course of is essential to make sure constant efficiency.

| Course of Step | Description | Instruments Used | High quality Checkpoints |

|---|---|---|---|

| Materials Choice | Deciding on applicable metal alloys with specified energy and ductility properties. | Materials specification sheets, chemical evaluation stories. | Materials certification, chemical composition verification. |

| Stamping | Shaping steel sheets into the specified type utilizing high-precision dies. | Stamping press, dies, measuring instruments. | Dimensional accuracy, floor end inspection, defect detection. |

| Machining | Refining dimensions and creating options utilizing lathes, milling machines, and so forth. | Lathes, milling machines, measuring instruments. | Dimensional accuracy, floor end inspection, burr removing. |

| Welding | Becoming a member of parts with sturdy and dependable welds. | Welding tools (spot welder, laser welder), measuring instruments. | Weld energy, penetration, visible inspection for defects. |

Security Requirements and Laws

Guaranteeing the protection of passengers and occupants is paramount within the automotive business. Air bag mounting plates, a essential part in automobile security methods, should adhere to stringent security requirements and laws to ensure dependable efficiency and forestall potential hurt. These laws embody your complete design, manufacturing, and testing course of, creating a sturdy framework for minimizing dangers.Understanding the precise security requirements and testing procedures for air bag mounting plates permits producers to develop and produce parts that meet stringent necessities.

This data is essential for avoiding potential liabilities and guaranteeing the protection of automobiles on the street. Non-compliance can have extreme penalties, impacting each the producer and the end-user.

Key Security Requirements and Laws

A complete understanding of the related security requirements is important for the manufacturing of protected and dependable air bag mounting plates. These requirements embody varied facets of design, materials choice, manufacturing processes, and testing procedures. Adherence to those requirements ensures that the parts carry out as anticipated throughout deployment, minimizing the chance of harm.

Testing Procedures and Standards

Thorough testing is essential to verify compliance with security requirements. Testing procedures usually contain subjecting the air bag mounting plate to numerous situations simulating real-world eventualities. This ensures that the plate can face up to the forces and stresses encountered throughout deployment, with out compromising security. Completely different testing strategies assess the plate’s resistance to influence, sturdiness, and its means to keep up structural integrity.

Potential Dangers and Penalties of Non-Compliance

Non-compliance with security requirements and laws may end up in vital dangers and penalties. These dangers vary from product defects to potential accidents to occupants in a automobile. Penalties can embrace pricey recollects, authorized repercussions, and harm to the producer’s popularity. Furthermore, the protection of passengers and occupants is instantly affected by the integrity and efficiency of those essential parts.

Regulatory Our bodies, Air bag mounting plate

A number of regulatory our bodies oversee the compliance of air bag mounting plate producers. These our bodies set up and implement requirements, conduct audits, and make sure that producers adhere to security laws. This oversight helps to keep up excessive security requirements and defend customers.

Compliance Necessities Desk

| Normal | Description | Testing Methodology | Compliance Necessities |

|---|---|---|---|

| Federal Motor Car Security Normal (FMVSS) 201 | Covers air bag methods, together with parts such because the mounting plate. | Impression testing, static load testing, fatigue testing. | Plates should face up to specified influence forces and stresses with out failure or deformation that compromises airbag deployment. |

| ISO 9001 | Worldwide customary for high quality administration methods. | Inside audits, course of documentation, high quality management procedures. | Manufacturing processes should be documented, managed, and persistently meet established high quality requirements. |

| SAE Worldwide Requirements | Requirements for varied facets of automotive engineering, together with air bag parts. | Specified testing procedures, together with sturdiness, materials properties, and dimensional tolerances. | The mounting plate should conform to outlined dimensions, materials properties, and efficiency traits. |

Consequence Abstract: Air Bag Mounting Plate

In conclusion, the air bag mounting plate is a crucial part of any fashionable automobile’s security system. This evaluation highlights the significance of correct design, manufacturing, and adherence to security laws. From deciding on the perfect materials to making sure rigorous high quality management, each facet contributes to the general efficiency and reliability of the airbag system. By totally understanding these essential concerns, producers can prioritize security and improve the effectiveness of those life-saving gadgets.

Question Decision

What are the most typical supplies utilized in air bag mounting plates?

Frequent supplies embrace high-strength metal alloys, aluminum alloys, and composites. The selection usually is determined by components like desired energy, weight, and price.

How do completely different automobile sorts have an effect on the design of air bag mounting plates?

Car dimension, weight distribution, and crash check necessities all affect the design. Bigger automobiles usually require stronger and extra sturdy mounting plates to face up to the influence forces.

What are the potential penalties of utilizing non-compliant air bag mounting plates?

Non-compliance can result in severe issues of safety, probably compromising the airbag’s means to deploy successfully throughout a crash. This might end in accidents or fatalities.

What are some examples of profitable air bag mounting plate designs?

Examples may embrace these from main automotive producers, highlighting revolutionary designs that prioritize security and effectivity. A deeper dive into these case research would showcase the very best practices.